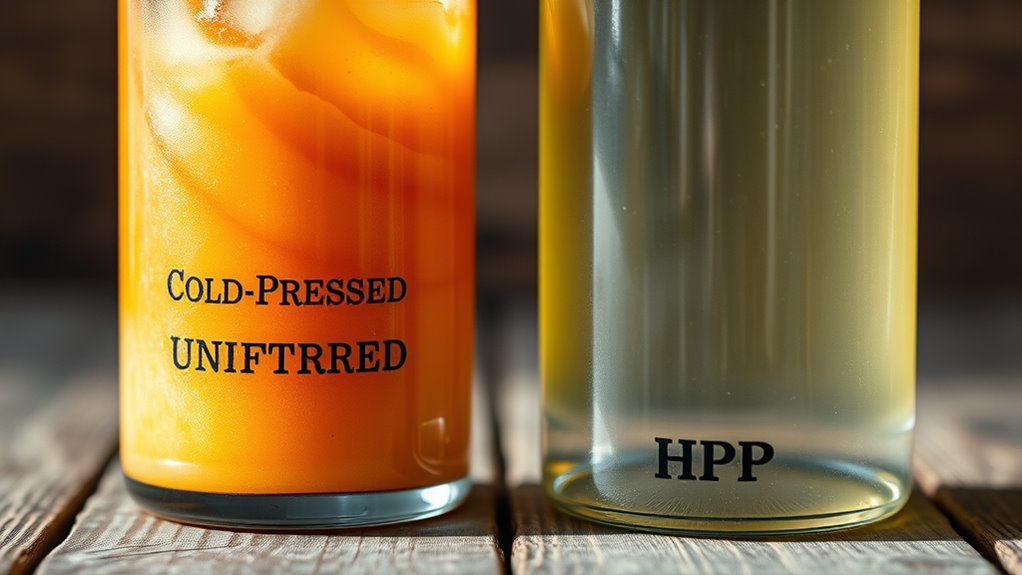

If you’re a natural purist, cold pressing keeps nutrients, enzymes, and delicate flavors intact by using minimal heat and mechanical pressure, offering vibrant, fresh-tasting products with rich textures. HPP uses high pressure to extend shelf life and preserve most nutrients, but can slightly diminish subtle flavors and aromas. Both methods have environmental pros and cons, so choosing depends on your priorities. To discover which process best aligns with your values, explore the details below.

Key Takeaways

- Cold pressing preserves delicate nutrients, enzymes, and natural flavors, appealing to purists seeking minimally processed juice.

- HPP extends shelf life while maintaining most nutrients, offering safety and convenience without heat, suitable for natural product consumers.

- Cold-pressed juices retain more vibrant aroma and richer texture, emphasizing authenticity valued by natural purity enthusiasts.

- HPP may involve artificial additives and milder flavors, which can reduce perceived naturalness for purist consumers.

- Both methods have environmental trade-offs: cold pressing produces more waste, while HPP consumes more energy, influencing eco-conscious choices.

How Cold-Pressing Preserves Natural Ingredients

Cold-pressing preserves natural ingredients by using minimal heat and mechanical pressure, which helps maintain the integrity of delicate nutrients. This method aligns with packaging innovation by reducing the need for artificial preservatives and additives, appealing to health-conscious consumers. As market trends favor clean, minimally processed products, cold-pressed items stand out for their freshness and nutritional value. You’ll find that the packaging for these products often emphasizes transparency and sustainability, reinforcing their natural appeal. This approach not only preserves flavor and nutrients but also extends shelf life without compromising quality. By adopting innovative packaging solutions, brands can better communicate their commitment to natural integrity, meeting the growing demand for raw, unprocessed options in today’s competitive marketplace. Natural preservation techniques play a crucial role in maintaining product quality and consumer trust, especially as consumers increasingly seek clean label products with authentic ingredients. Incorporating sustainable packaging further enhances the product’s appeal to environmentally conscious buyers. Additionally, minimally processed methods like cold-pressing are favored because they retain more nutrients compared to traditional processing techniques. Furthermore, employing advanced packaging technology can help extend shelf life while preserving the product’s natural qualities.

The Science Behind High-Pressure Processing

High-Pressure Processing (HPP) harnesses intense pressure rather than heat to preserve food’s freshness and nutrients. This method works by disrupting cellular structures, which slows enzymatic activity and halts spoilage. It also effectively inactivates microbes, extending shelf life without compromising quality. Additionally, the contrast ratio in imaging technology plays a crucial role in enhancing visual detail, akin to how HPP preserves the integrity of food textures and flavors. Moreover, applying mindful practices during processing can further enhance product quality by reducing oxidative stress and promoting a sense of well-being among consumers. Furthermore, the precise application of pressure ensures minimal impact on the food’s original qualities, making it a favored technique among natural food enthusiasts. Understanding the nutritional profile of foods processed with HPP highlights its ability to retain more vitamins and antioxidants compared to traditional methods.

Comparing Nutritional Benefits and Quality

When it comes to preserving nutrients and quality, both cold-pressed and HPP methods excel in retaining the natural integrity of foods, but they do so through different mechanisms. Cold-pressing uses gentle extraction techniques that avoid heat, helping vitamins, enzymes, and antioxidants stay intact, which often results in higher nutritional content. HPP, on the other hand, applies high pressure to eliminate microbes, extending shelf stability without the need for added preservatives. This process preserves most nutrients effectively, though some delicate compounds might degrade slightly. Ultimately, both methods deliver high-quality products, but your choice depends on whether you prioritize maximum nutrient retention through extraction techniques or longer shelf life without compromising natural qualities.

Flavor Profiles and Sensory Experience

You’ll notice that cold-pressed juices often retain a fresher aroma and more vibrant flavor, while HPP juices can have a milder scent. Texture and mouthfeel also differ, with cold-pressed options feeling richer and more natural. These differences influence how intense and nuanced each juice tastes on your palate. Additionally, the shelf life of fresh juices varies depending on processing methods, affecting how long you can enjoy them at their best. Understanding the preservation techniques can help you choose the best option for your preferences and needs. For example, the processing methods can impact nutrient retention and overall quality over time. Moreover, nutritional advantages of cold-pressed juices often include higher vitamin and antioxidant levels compared to HPP counterparts.

Freshness and Aroma Preservation

Freshness and aroma are key to enjoying the true flavor of your beverages, and the method used to process them plays a crucial role in preserving these qualities. Cold-pressed techniques retain more of the original aroma because they minimize heat, which can degrade volatile compounds. HPP also preserves freshness but relies heavily on ideal harvest timing and storage conditions to maintain flavor integrity. To maximize aroma preservation, consider these factors:

- Harvest at peak ripeness to lock in fresh flavors and aromatic compounds.

- Store ingredients under proper conditions to prevent oxidation and spoilage.

- Use gentle processing methods to avoid heat or pressure that can diminish aroma intensity.

- Proper ventilation and safe handling during processing can further help preserve the delicate aromatic profile.

- Additionally, controlling processing environment variables such as temperature and humidity can significantly impact aroma retention and overall product quality.

Texture and Mouthfeel Differences

The processing methods of cold-pressed and HPP substantially influence the texture and mouthfeel of beverages, shaping your sensory experience from the first sip. Cold-pressed juices often deliver a richer, more pronounced textural contrast, with pulp and fiber residuals providing a satisfying thickness. In contrast, HPP preserves a smoother, more uniform mouthfeel, free from pulp or graininess. These mouthfeel nuances affect how you perceive freshness and body in each drink. Cold-pressed beverages might feel more substantial, engaging your palate with a robust, chewy sensation, while HPP products offer a cleaner, lighter texture. Your preference depends on whether you value a lively, textured experience or a silky, refined mouthfeel, both shaped by the distinct processing techniques. Additionally, the preservation of natural enzymes and nutrients in cold-pressed methods can contribute to a more vigorous mouthfeel and flavor profile. The choice of processing method also influences the product’s shelf life, which can impact freshness and sensory qualities over time. Moreover, some consumers associate the texture and mouthfeel with the overall impression of quality and freshness in beverages.

Flavor Intensity and Nuance

Processing methods markedly influence the flavor intensity and nuanced profiles of beverages. Cold-pressed techniques preserve natural flavors, offering a rich, authentic taste, while HPP can sometimes diminish subtle notes. When artificial additives are used, they often mask natural flavors, reducing complexity and depth.

To deepen your understanding:

- Cold-pressed drinks typically showcase vibrant, fresh flavors with minimal masking.

- HPP may result in a smoother, milder profile but can compromise delicate nuances.

- Artificial additives are commonly used to enhance or mask certain flavors, often at the expense of authenticity.

As a natural purist, you’ll notice that flavor intensity isn’t just about strength but also about nuance, which processing methods can notably influence.

Environmental Impact and Sustainability Factors

While both cold-pressed and HPP methods aim to preserve nutrients and extend shelf life, they differ markedly in their environmental impacts. Cold pressing typically involves minimal energy use, resulting in a lower carbon footprint, but it may produce more waste that requires careful recycling practices. In contrast, HPP consumes significant energy due to high-pressure equipment, increasing its carbon footprint. However, HPP often generates less waste, which can simplify recycling efforts. If sustainability is your priority, cold pressing’s lower energy demands and straightforward waste management might appeal more. Additionally, understanding the energy requirements involved in each process can help you make more environmentally conscious decisions. Furthermore, considering the environmental footprint of each technique can guide you toward more sustainable food processing choices. Innovations in energy-efficient technologies, such as renewable energy-powered equipment, could further influence the environmental impact of these methods in the future. For example, adopting renewable energy sources in food processing facilities can significantly reduce overall food waste and environmental harm associated with food processing techniques.

Choosing the Right Method for True Natural Purity

Choosing the right method for true natural purity depends on your priorities for quality, flavor, and nutrient integrity. Cold-pressed juice preserves maximum nutrients and vibrant flavors through minimal processing, appealing to purists. Conversely, HPP maintains freshness and extends shelf life without heat, aligning with consumer preferences for convenience and safety. To decide, consider these factors:

- Packaging innovations, such as eco-friendly or airtight containers, influence freshness and sustainability.

- Consumer preferences for minimally processed, preservative-free products might favor cold-pressing.

- The importance of nutrient retention and flavor intensity can guide your choice toward cold-pressed, or toward HPP for longer shelf life.

Ultimately, understanding how packaging and consumer demands shape each method helps you select the best approach for authentic natural purity.

Frequently Asked Questions

Which Method Retains More Live Enzymes in the Final Product?

You’re wondering which method retains more live enzymes in the final product. Cold-pressed techniques excel at enzyme preservation because they use minimal heat, ensuring better nutrient retention. In contrast, HPP applies high pressure but can slightly degrade some enzymes over time. So, if maintaining live enzymes is your priority, cold-pressed products generally offer superior enzyme preservation, helping you get the most nutrient retention and health benefits from your juice.

Are There Any Health Risks Associated With HPP or Cold-Pressing?

Think of choosing a juice like selecting a vehicle—some are smoother, some riskier. With HPP and cold-pressing, toxicity concerns are minimal, but allergy risks can still exist if you’re sensitive to certain ingredients. Both methods are generally safe; however, rare cases of contamination or allergic reactions highlight the importance of knowing your sources. Always check labels and consult your doctor if you have specific health concerns.

How Do Processing Times Compare Between Cold-Pressing and HPP?

When comparing processing durations, cold-pressing usually takes longer than HPP, affecting manufacturing speed. Cold-pressing involves slow extraction, which preserves nutrients but extends production time. In contrast, HPP uses high pressure to quickly process products, increasing manufacturing efficiency. If you want faster turnaround, HPP offers a quicker processing time. However, if you prioritize nutrient retention, cold-pressing’s longer processing duration might be worth the wait.

Can Both Methods Be Used for All Types of Produce?

Imagine a garden with diverse plants—some thrive in the sun, others in shade. Similarly, not all produce benefits from one processing method. Cold pressing and HPP each have produce versatility, but their suitability varies. Cold pressing preserves flavor well for delicate items like berries, while HPP suits sturdier produce like leafy greens. You need to choose based on produce type to maximize flavor preservation and quality.

What Are the Cost Differences for Producers Choosing Each Method?

You’ll find that cold-pressed methods generally have higher production costs due to slower processing and more labor-intensive steps. Equipment investment is also significant, as cold-press machines are often costly upfront. In contrast, HPP involves high-pressure equipment, which can be expensive initially but offers faster throughput. So, your decision depends on balancing higher upfront costs with operational efficiency and product quality when choosing between the two methods.

Conclusion

Ultimately, both cold-pressing and HPP keep your products close to nature, so you get fresh, pure flavors. Yes, HPP might seem high-tech, but it’s just another way to preserve nutrients without heat or chemicals. If you’re a true natural purist, choose the method that aligns with your values—both deliver quality and safety. So, don’t worry about the tech; focus on what matters most—authentic, healthy, and delicious products made just for you.

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.