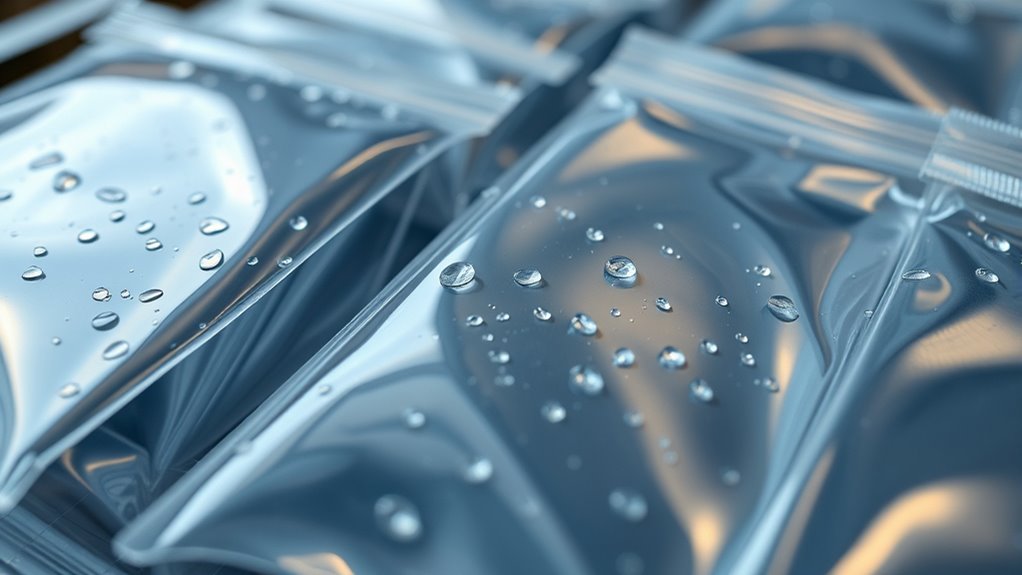

In humid Augusts, maintaining heat-seal integrity is essential. To do this, control environmental humidity with dehumidifiers and keep temperatures stable, preventing moisture from weakening seals. Choose moisture-resistant materials and proper sealants to withstand humidity impacts. Regularly test and monitor your sealing equipment, ensuring consistent temperature and pressure settings. Proper handling and storage also help. Continue exploring effective strategies to keep seals strong despite high humidity conditions.

Key Takeaways

- Control ambient humidity with dehumidifiers or air conditioning during sealing processes to prevent moisture interference.

- Select moisture-resistant films and compatible sealants proven to perform reliably in humid conditions.

- Maintain precise temperature and pressure controls, regularly calibrating equipment to ensure consistent seals.

- Pre-condition packaging environments and handle materials carefully to minimize moisture exposure before sealing.

- Conduct regular inspections and leak tests to verify seal integrity, especially in high-humidity months like August.

Understanding How Humidity Affects Heat-Sealing Processes

Humidity levels can markedly impact the effectiveness of heat-sealing processes. High humidity introduces moisture into the environment, which can interfere with the sealing material’s ability to bond properly. These humidity effects often lead to seal degradation, where the integrity of the seal diminishes over time. Moisture can cause uneven melting or prevent the material from adhering uniformly, resulting in weak spots. When the environment is excessively humid, you might notice seals that appear intact initially but deteriorate prematurely. Controlling humidity during the heat-sealing process is vital to maintain consistent seal quality. Understanding how humidity influences your sealing results helps you troubleshoot issues early, ensuring your packages stay secure and intact through their shelf life. Additionally, awareness of environmental factors aligns with best practices in environmental control, emphasizing the importance of controlling variables to maintain system security and integrity. Proper humidity regulation can prevent unforeseen issues and enhance overall sealing performance. Furthermore, implementing humidity monitoring systems can provide real-time data to optimize sealing conditions efficiently.

Selecting the Right Materials for Humid Conditions

When working in humid conditions, choosing moisture-resistant films and compatible sealants is essential for maintaining heat-seal integrity. You need materials that can withstand moisture without compromising the seal, so understanding environmental testing standards is vital. Conducting performance testing ensures the materials will hold up under humid conditions, providing reliable, durable seals in challenging environments. Additionally, selecting materials with proven moisture resistance can significantly reduce the risk of seal failure caused by humidity. Incorporating industry standards into your material selection process further enhances the reliability of the seals in humid environments. Furthermore, understanding tuning modifications in vehicles can help optimize performance and durability in various conditions.

Moisture-Resistant Films

Are you selecting the right materials to guarantee your heat-seal remains intact in humid conditions? Moisture-resistant films are essential for this. Look for materials with strong moisture barriers that prevent water vapor from penetrating the package. These films enhance humidity resistance, ensuring your seals stay secure even during high humidity or sudden temperature changes. Choose options like laminated films or specialized polymer blends designed specifically to block moisture transfer. In addition, creating an airtight seal can further improve moisture resistance by limiting the exposure of the package to external humidity. Properly sealed packages can also prevent moisture migration, which is crucial for maintaining product quality in humid environments. A high-quality moisture barrier film often incorporates advanced polymer technology to improve effectiveness. Additionally, selecting films with certified moisture barrier properties can provide extra assurance of performance under challenging conditions. By using these moisture-resistant films, you reduce the risk of seal failure caused by moisture infiltration. This keeps your product protected and maintains package integrity throughout storage and transportation. Incorporating effective filtration and pump protection can also help prevent contamination and ensure consistent sealing performance in humid environments. Selecting the appropriate moisture barrier material is a smart step toward consistent, reliable heat-seal performance.

Compatible Sealants Selection

Choosing compatible sealants is crucial to guarantee your heat seals hold up in humid conditions. You need sealants with proven compatibility and strong adhesive properties to prevent failures. Selecting the right materials involves understanding how different sealants interact with your films and packaging. Here’s a quick guide:

| Sealant Type | Key Characteristics |

|---|---|

| Hot Melt | Fast bonding, good flexibility |

| Acrylic | Excellent adhesion, UV resistance |

| Polyurethane | Superior flexibility, moisture resistance |

| EVA | Good seal strength, compatible with films |

Match your sealant choice with your packaging needs, ensuring sealant compatibility and ideal adhesive properties. This reduces the risk of seal failure during humid months and enhances overall integrity. Considering the paint sprayer options available can also improve your coating application, ensuring even coverage and durability in challenging environments. Additionally, understanding how environmental factors like humidity affect sealant performance can help in selecting materials that maintain their integrity over time. Properly selected sealants can also contribute to heat-seal integrity by maintaining adhesion despite fluctuating humidity levels. Being aware of humidity’s impact on materials can further assist in choosing sealants that perform reliably in moist conditions. Recognizing how moisture influences sealant adhesion can lead to more effective material selection and longer-lasting seals.

Environmental Testing Standards

Selecting the right sealants for humid conditions requires more than just understanding their compatibility; it also involves verifying that they meet specific environmental testing standards. These standards ensure that sealants can withstand thermal expansion caused by temperature fluctuations, preventing seal deformation over time. By subjecting materials to rigorous tests, you can confirm their ability to maintain integrity despite humidity and thermal stress. Proper testing helps identify sealants that resist excessive deformation or cracking, which can compromise heat-seal performance. Meeting standards like ASTM or ISO guarantees your materials are reliable under real-world conditions. Additionally, understanding the impact of environmental factors on sealant durability can help you choose the most resilient sealants for your application. Conducting regular inspections and monitoring environmental conditions can further extend the lifespan of your heat-seals in humid settings. Incorporating pre-approved materials that have undergone such testing can streamline your selection process and ensure compliance. Furthermore, considering moisture resistance in sealant selection enhances long-term performance in humid environments.

Optimizing Temperature and Pressure Settings for Reliable Seals

To guarantee your seals are dependable, you need to carefully control the temperature and pressure during the process. Precise temperature settings prevent weak or burned seals, while consistent pressure guarantees uniform contact. Paying close attention to these factors will considerably improve your sealing reliability. Additionally, monitoring engine performance adjustments can help ensure optimal operating conditions for sealing materials.

Precise Temperature Control

Achieving reliable heat-seal integrity hinges on maintaining precise temperature control throughout the sealing process. Temperature stability ensures consistent bonding, preventing weak seals or damage. Calibration accuracy is critical; even minor deviations can compromise seal quality. To optimize control, regularly verify your equipment’s temperature settings and monitor fluctuations. Use high-quality sensors for real-time feedback, and adjust the sealing parameters accordingly. Maintaining strict control helps mitigate humidity effects and prevents overheating.

- Regularly calibrate your sealing equipment for accuracy

- Use sensors with high temperature resolution

- Monitor temperature fluctuations during sealing operations

Consistent Pressure Application

Maintaining consistent pressure during the heat-sealing process is essential for achieving reliable seals. Uneven pressure can result in weak spots or incomplete seal application, especially in humid conditions. To guarantee uniform pressure, regularly calibrate your equipment, verifying that pressure settings match manufacturer specifications. Proper equipment calibration guarantees that the pressure applied is neither too high nor too low, which is critical for seal integrity. During seal application, monitor pressure levels closely and make adjustments as needed to prevent inconsistencies. Consistent pressure helps maintain ideal contact between sealing surfaces, reducing the risk of seal failure. By focusing on proper equipment calibration and applying uniform pressure, you improve the reliability of each seal, even in challenging, humid environments.

Pre-Conditioning Packaging Environments for Consistent Results

Ensuring consistent heat-seal integrity starts with properly pre-conditioning your packaging environment. Managing humidity levels and implementing effective environmental controls help create stable conditions, reducing seal failures. By controlling temperature and moisture, you prevent excess humidity from weakening seal strength or causing inconsistent adhesion. Proper pre-conditioning minimizes moisture-related issues, especially during humid Augusts.

Consider these key steps:

- Use dehumidifiers or air conditioners to regulate ambient humidity

- Maintain stable temperatures to prevent condensation

- Monitor environmental conditions regularly for fluctuations

Implementing Proper Storage and Handling Practices

Proper storage and handling practices are essential for preserving heat-seal integrity and preventing damage before packaging. When you handle materials carefully, you minimize the risk of scratches, tears, or contamination that can compromise seal quality. Store packaging materials in a cool, dry environment, away from humidity and direct sunlight, to prevent moisture absorption that weakens seals. Proper stacking and transportation prevent deformation, which could affect packaging aesthetics. Maintaining pristine packaging enhances customer perception by ensuring products arrive in perfect condition. Training staff on handling procedures and using appropriate tools reduces mishandling risks. Consistent storage conditions and careful handling directly contribute to the durability of seals and uphold the professional look that influences customer trust and satisfaction.

Conducting Regular Seal Integrity Testing and Inspection

Regularly testing and inspecting your heat seals is crucial to catch potential failures early and prevent product spoilage or customer complaints. Consistent inspection routines help you guarantee ideal seal quality and identify issues before they escalate. By implementing routine checks, you reduce the risk of compromised seals during humid conditions. Effective inspection methods include visual examinations, peel tests, and leak detection. These practices allow you to monitor seal integrity under different environmental conditions and maintain high standards. Establishing a schedule for regular seal testing ensures that issues are addressed promptly, safeguarding product freshness and brand reputation. Remember, proactive inspection routines are key to maintaining reliable heat-seal integrity, especially during challenging weather like humid Augusts.

- Visual inspection for visible damage or gaps

- Peel testing for seal strength

- Leak detection for airtightness

Troubleshooting Common Heat-Sealing Issues in Humid Weather

Humidity can considerably impact heat-sealing performance, causing seals to weaken or fail altogether. When facing seal failure in humid conditions, check your equipment calibration first—improper settings often cause inconsistent seals. Poor calibration can lead to insufficient heat or pressure, worsening seal integrity. To troubleshoot, consider these common issues:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Weak or incomplete seals | High humidity affecting materials | Adjust equipment calibration for ideal temperature and pressure |

| Seal failure | Equipment not calibrated correctly | Regularly calibrate your sealers before use |

| Uneven sealing | Moisture on materials or equipment | Keep surfaces dry and clean before sealing |

| Seal cracks or breaks | Excessive humidity causing material failure | Use dehumidifiers or control ambient humidity |

Addressing calibration and environment helps maintain reliable seals in humid weather.

Innovative Technologies and Equipment to Enhance Seal Performance

Advancements in heat-sealing technology are transforming how you can achieve stronger and more reliable seals, even in challenging conditions. With innovative sealing methods and advanced equipment, you can improve seal integrity in humid weather. These innovations include smart temperature control systems, high-performance sealing materials, and precision pressure regulation. Such tools help you adapt to moisture-rich environments, ensuring consistent seals. By integrating these technologies, you reduce failures caused by humidity, saving time and materials. The latest equipment also offers real-time monitoring, allowing you to make immediate adjustments. Embracing these innovations empowers you to enhance seal quality, maintain product safety, and meet rigorous standards despite environmental challenges. Staying ahead with cutting-edge solutions means your seals stay intact, no matter the weather.

Frequently Asked Questions

How Does Humidity Impact the Shelf Life of Heat-Sealed Packages?

Humidity effects can considerably impact the shelf life of your heat-sealed packages. When humidity is high, it can weaken the seal material, making it more prone to leaks or failures over time. This reduces the package’s ability to protect contents from moisture and contamination. To maintain ideal shelf life, verify your sealing process accounts for humidity variations, using appropriate seal materials that resist moisture and maintain integrity despite humidity fluctuations.

Can Specific Additives Improve Seal Durability in High-Humidity Environments?

You wonder if seal additives can boost durability in humid conditions. While moisture barriers protect packages from humidity, seal additives strengthen the bond itself, making it more resistant to moisture intrusion. Combining specific seal additives with effective moisture barriers creates a dual defense, enhancing seal integrity. This synergy guarantees your packages stay secure longer, even in high-humidity environments, ultimately preserving product quality and extending shelf life.

Are There Environmental Standards for Packaging in Humid Climates?

You should be aware that packaging regulations often set standards for environmental safety and durability, especially in humid climates. Climate adaptation is vital, and regulations may specify materials and methods to guarantee packaging remains intact in moisture-rich environments. By following these standards, you can improve product protection, reduce waste, and comply with legal requirements. Always stay updated on regional guidelines to make certain your packaging effectively adapts to challenging weather conditions.

How Do Humidity Levels Vary Across Different Geographic Regions?

You should understand that humidity levels vary widely across different geographic regions due to regional climate differences. Humidity mapping helps identify these variations, showing where high or low humidity persists. In humid regions, expect consistently higher moisture levels, which can impact packaging. Knowing these regional climate patterns allows you to adjust your packaging strategies accordingly, ensuring heat‑seal integrity and product protection, especially during humid months like August.

What Are the Cost Implications of Enhanced Sealing Techniques in Humid Conditions?

Like a tight knot holding everything together, enhanced sealing techniques strengthen your packaging, but they come with costs. You’ll see higher sealant costs upfront, and maintenance expenses may increase as you guarantee ideal performance in humid conditions. While these investments might seem hefty now, they save you from costly rework, spoilage, and customer dissatisfaction later. Ultimately, investing in better seals is a small price to pay for peace of mind and product integrity.

Conclusion

To guarantee your heat seals stay strong in humid August weather, remember that humidity can reduce seal strength by up to 30%. By selecting suitable materials, adjusting your settings, and pre-conditioning your environment, you can maintain reliable seals. Regular testing and proper handling are also key. With these steps, you’ll improve consistency and prevent costly failures, even during the most challenging weather conditions. Stay proactive, and your seals will perform flawlessly every time.

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.