Juice Manufacturing Process

9 Best Steps in Industrial Juice Manufacturing Process

We’ve all savored a delightful glass of juice, but have you ever pondered the methodology behind its production?

Well, in this article, we’re going to take you through the 9 best steps in the industrial juice manufacturing process.

From harvesting and selecting the raw fruits to packaging and labeling the final product, we’ll give you a practical and knowledgeable insight into how your favorite juices are made.

So, sit back, relax, and let’s dive into the world of industrial juice manufacturing.

Key Takeaways

- The process of industrial juice manufacturing involves carefully selecting and harvesting raw fruits, ensuring they are ripe and fresh.

- Cleaning and sanitizing the fruits is crucial to prevent contamination and remove dirt and contaminants.

- Juice extraction techniques such as mechanical and enzymatic methods are used to extract the juice from the fruits while retaining optimal flavor and nutrients.

- Filtering, clarifying, and pasteurizing the juice are essential steps to ensure a smooth, clear, and safe final product with an extended shelf life.

Harvesting and Selecting Raw Fruits

In our industrial juice manufacturing process, we begin by carefully selecting and harvesting the raw fruits that will become the foundation of our delicious beverages. We understand the importance of using high-quality fruits to create the best possible juices for our customers. Our team of experts meticulously examines each fruit, ensuring that only the ripest and freshest ones are chosen. We take pride in sourcing our fruits from trusted farmers who share our commitment to quality. By handpicking the fruits, we can guarantee that only the best ones make it into our juicing process.

This attention to detail allows us to create juices that are bursting with flavor and packed with nutrients. As we move forward, the next crucial step in our process is cleaning and sanitizing the fruits to ensure the highest standards of hygiene and safety.

Cleaning and Sanitizing Fruits

When it comes to manufacturing juice, ensuring fruit hygiene is of utmost importance. To achieve this, effective cleaning techniques must be employed to remove any dirt, pesticides, or other contaminants from the fruits.

Additionally, sanitizing methods should be implemented to ensure the safety of the final product.

Fruit Hygiene Importance

To ensure the safety and quality of our industrial juice products, we prioritize the thorough cleaning and sanitization of fruits.

Fruit hygiene is of utmost importance in our manufacturing process, as it helps prevent contamination and ensures the freshness of our juices.

Before processing, all fruits are carefully inspected to remove any damaged or spoiled pieces. They’re then washed using a combination of water and food-grade sanitizers to eliminate any potential pathogens or residues.

This step is crucial in maintaining the integrity of our products and meeting the highest hygiene standards. Additionally, our cleaning protocols are constantly reviewed and updated to stay in line with industry best practices.

Effective Cleaning Techniques

We prioritize effective cleaning techniques, using a combination of water and food-grade sanitizers, to ensure the safety and quality of our industrial juice products. To achieve this, we follow a rigorous cleaning process that involves the following steps:

- Pre-washing: We begin by rinsing the fruits thoroughly with water to remove any visible dirt or debris.

- Sanitizing: After pre-washing, we use food-grade sanitizers to kill any remaining bacteria or pathogens on the fruit’s surface.

These cleaning techniques are crucial in eliminating potential contaminants and ensuring that our industrial juice products meet the highest standards of hygiene.

Sanitizing Methods for Safety

After pre-washing and removing visible dirt or debris from the fruits, we proceed to sanitize them using food-grade sanitizers.

Sanitizing the fruits is a crucial step in ensuring the safety of the juice manufacturing process. Food-grade sanitizers effectively eliminate harmful bacteria and pathogens that may be present on the fruit’s surface.

To sanitize the fruits, we immerse them in a solution of food-grade sanitizer for a specific period of time. This allows the sanitizer to penetrate and eliminate any remaining contaminants. It’s important to follow the manufacturer’s instructions for dilution and contact time to ensure maximum effectiveness.

Once the fruits have been properly sanitized, we can confidently move on to the next step of extracting juice from them.

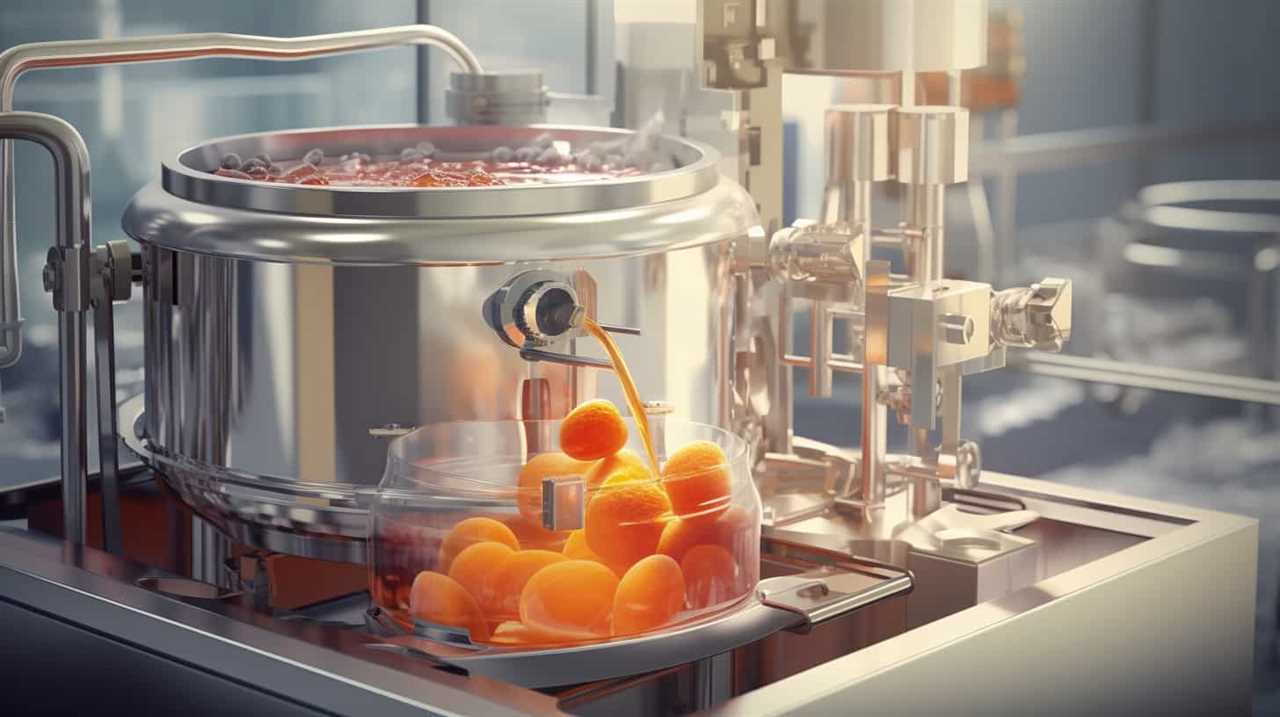

Extracting Juice From Fruits

When extracting juice from fruits, our team utilizes a combination of mechanical and enzymatic methods to ensure optimal flavor and nutrient retention. This allows us to provide our customers with the highest quality juice possible.

Here are the steps we follow to extract juice from fruits:

- Mechanical extraction:

- Crushing and pressing: We use specialized machinery to crush the fruits and extract the juice by pressing them.

- Centrifugal force: By spinning the crushed fruits rapidly, we separate the juice from the pulp.

- Enzymatic extraction:

- Enzyme treatment: We add enzymes to the crushed fruits to break down the cell walls and release the juice.

- Maceration: The fruits are soaked in enzymes to further enhance the extraction process.

Filtering and Clarifying the Juice

To filter and clarify the juice, our team utilizes a combination of methods to remove any impurities and ensure a smooth and clear final product.

First, the juice is passed through a coarse filter to remove larger particles such as pulp and seeds.

Next, it undergoes a process called clarification, where enzymes or natural settling agents are added to help separate any remaining solids from the liquid.

This mixture is then allowed to settle, and the clear juice is carefully decanted or siphoned off, leaving behind any sediment.

Finally, the juice is passed through a fine filter to remove any microscopic impurities and ensure its purity.

Pasteurizing the Juice for Safety

To ensure the safety of our juice, we employ the process of pasteurization. This essential step involves heating the juice to a specific temperature for a predetermined amount of time to kill harmful bacteria and pathogens.

Here’s why pasteurization is crucial in the manufacturing of industrial juice:

- It eliminates harmful microorganisms: Pasteurization effectively destroys bacteria, yeast, and molds that may be present in the juice, ensuring it’s safe for consumption.

- It extends shelf life: By eliminating spoilage-causing organisms, pasteurization helps prevent the juice from deteriorating quickly, allowing it to have a longer shelf life. This reduces waste and increases profitability for juice manufacturers.

- It preserves nutritional value: Pasteurization minimally affects the juice’s nutritional content, allowing consumers to enjoy the health benefits of the fruits or vegetables used.

With the juice now safely pasteurized, we can move on to the next step of adding preservatives and flavorings to enhance taste and prolong shelf life.

Adding Preservatives and Flavorings

When it comes to adding preservatives and flavorings in the industrial juice manufacturing process, there are several important points to consider.

Firstly, the types of preservatives available, such as natural or artificial options, can impact the shelf life and safety of the juice.

Secondly, the choice of flavorings, whether it’s natural extracts or artificial additives, can greatly influence the taste and appeal of the final product.

Lastly, it’s crucial to understand the potential effect of these additives on the overall quality of the juice, ensuring that they enhance rather than compromise its nutritional value.

Types of Preservatives

We add preservatives and flavorings to our industrial juice manufacturing process. Preservatives are substances that help extend the shelf life of our juice products, ensuring that they remain fresh and safe for consumption. There are different types of preservatives that we use, including:

- Natural preservatives:

- Citric acid: Derived from citrus fruits, it acts as an antioxidant and helps to inhibit the growth of bacteria and mold.

- Vitamin C: Also known as ascorbic acid, it not only acts as a preservative but also enhances the flavor and color of the juice.

- Synthetic preservatives:

- Sodium benzoate: Effective against yeast, bacteria, and mold, it’s commonly used in acidic juices.

- Potassium sorbate: It prevents the growth of yeast, mold, and fungi in various juice products.

Flavoring Options Available

Regularly, we incorporate various flavoring options into our industrial juice manufacturing process, along with the addition of preservatives. Our goal is to create a wide range of flavors that cater to the diverse preferences of our customers. We carefully select high-quality flavorings that are natural and free from any artificial additives. Some of the popular flavorings we use include fruit essences, extracts, and concentrates. These flavorings not only enhance the taste of the juice but also provide a vibrant and refreshing experience for the consumers.

We understand the importance of maintaining the integrity of the juice while adding flavorings, which is why we follow strict quality control measures throughout the manufacturing process. By carefully balancing the flavorings and preservatives, we ensure that the final product meets the highest standards of taste and quality.

Transitioning into the subsequent section about the effect on juice quality, it’s essential to understand how the addition of flavorings and preservatives impacts the overall quality of the juice.

Effect on Juice Quality

The addition of preservatives and flavorings significantly influences the overall quality of the juice. When it comes to preserving the freshness and extending the shelf life of the juice, certain preservatives are added. These include natural preservatives like citric acid and ascorbic acid, as well as artificial preservatives such as sodium benzoate and potassium sorbate.

On the other hand, flavorings are added to enhance the taste and aroma of the juice. These can be natural flavors extracted from fruits or artificial flavors created in a laboratory. While preservatives help maintain the juice’s quality over time, flavorings ensure a delightful and enjoyable drinking experience.

Both preservatives and flavorings must be carefully chosen and properly balanced to create a high-quality juice that satisfies the taste buds of consumers.

As we move on to the next section, we’ll explore the crucial steps in packaging and labeling the juice.

Packaging and Labeling the Juice

During the industrial juice manufacturing process, one important step is to carefully package and label the juice. Proper packaging and labeling ensure that the juice remains fresh and safe for consumption while also providing important information to consumers. To grab the attention of our audience, let’s take a look at a table that highlights the key elements of packaging and labeling:

| Packaging | Labeling | Benefits |

|---|---|---|

| Airtight containers | Clear and concise information | Preserves freshness |

| Tamper-evident seals | Nutritional facts and ingredients | Ensures product integrity |

| Protective packaging materials | Allergen warnings | Prevents damage during transit |

| Eco-friendly packaging options | Expiration date | Appeals to environmentally conscious consumers |

Quality Control and Testing

To ensure the highest quality of juice production, we prioritize rigorous quality control and testing throughout our manufacturing process.

Our commitment to quality starts with carefully selecting the finest fruits and ingredients. We conduct thorough inspections to ensure that only the best raw materials are used.

In addition, we’ve implemented advanced testing methods to analyze the juice at various stages of production. This includes testing for flavor, color, consistency, and nutritional value.

Our dedicated team of experts meticulously monitors every aspect of the manufacturing process, from the initial blending to the final packaging.

We also conduct regular audits to ensure that our facilities and equipment meet the highest standards of cleanliness and safety.

Storage and Distribution of the Juice

How do we ensure the proper storage and distribution of our carefully crafted juice? It is crucial to maintain the quality and freshness of our juice throughout the storage and distribution process. We follow strict guidelines to ensure that our juice reaches customers in the best possible condition. Here is a table outlining our storage and distribution practices:

| Storage | Distribution |

|---|---|

| – Temperature-controlled warehouses | – Efficient logistics system |

| – Regular quality checks | – Reliable transportation |

| – Proper labeling and packaging | – Timely delivery |

| – FIFO (First In, First Out) method | – Collaboration with trusted retailers |

Frequently Asked Questions

What Are the Various Sanitation Methods Used in Cleaning and Sanitizing Fruits for Juice Manufacturing?

For cleaning and sanitizing fruits in juice manufacturing, we use various sanitation methods. These methods ensure that the fruits are free from harmful bacteria and contaminants, maintaining high standards of cleanliness and safety.

Are There Any Specific Fruits That Are More Challenging to Extract Juice From?

Yes, there are certain fruits that can pose challenges in extracting juice. However, with our expertise and efficient processes, we have developed effective techniques to overcome these challenges and ensure high-quality juice production.

How Does the Filtering and Clarifying Process Contribute to the Overall Quality of the Juice?

Filtering and clarifying the juice is crucial for ensuring its overall quality. These processes remove impurities, sediment, and any remaining solids, resulting in a clear and pure juice that meets the highest standards of taste and safety.

What Temperature and Duration Are Typically Used During the Pasteurization Process to Ensure the Safety of the Juice?

To ensure the safety of the juice, we typically use high temperatures and a specific duration during the pasteurization process. This step acts as a protective shield, eliminating harmful bacteria and preserving the juice’s freshness.

What Factors Are Considered When Selecting Preservatives and Flavorings for Industrial Juice Manufacturing?

When selecting preservatives and flavorings for industrial juice manufacturing, we consider factors such as safety, taste, shelf life, and customer preferences. It’s important to choose ingredients that meet regulatory standards and enhance the overall quality of the product.

Conclusion

In conclusion, the industrial juice manufacturing process is a well-oiled machine that ensures the highest quality and safety standards. From carefully selecting the freshest fruits to the precise filtering and pasteurization techniques, every step is carried out with meticulous attention.

The addition of preservatives and flavorings further enhances the taste and shelf life of the juice. With rigorous quality control and testing, consumers can trust that they’re getting the best possible product.

From start to finish, the process is a testament to the practicality and expertise of the industry.

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.

Juice Manufacturing Process

Why Opt for Top-Notch Materials in Beverage Packaging?

We select only the finest materials for our beverage packaging because they form the basis of our commitment to excellence.

By opting for top-notch materials, we ensure that our packaging is strong, reliable, and visually appealing.

This article explores the importance of quality materials, the benefits of using top-notch packaging, and the factors to consider when selecting them.

We will also discuss the top materials for juice packaging and sustainable options for beverage packaging.

Join us as we elevate the art of serving others through exceptional packaging.

Key Takeaways

- Quality materials ensure durability and safety of packaging.

- Investing in top-notch materials reduces the risk of damage or leaks during transportation and storage.

- Enhanced product protection against light, moisture, and oxygen.

- Premium packaging materials create a positive brand image.

Importance of Quality Materials

Quality materials are essential for ensuring the durability and safety of beverage packaging. By using high-quality materials, companies can achieve cost efficiency and customer satisfaction. Investing in top-notch materials may seem expensive at first, but it proves to be cost-efficient in the long run. Quality materials ensure that the packaging can withstand the rigors of transportation and storage, reducing the risk of damage or leaks. This not only minimizes the need for costly replacements but also prevents potential customer dissatisfaction due to faulty packaging.

Benefits of Using Top-Notch Packaging

When it comes to beverage packaging, we greatly benefit from using top-notch materials. The advantages of using high-quality packaging materials are numerous and can greatly impact the success of a beverage product.

Here are three key advantages:

- Enhanced product protection: Top-notch materials provide superior protection against external factors such as light, moisture, and oxygen. This helps to maintain the freshness and quality of the beverage, ensuring it reaches the consumer in the best possible condition.

- Increased shelf life: High-quality packaging materials can extend the shelf life of beverages by preventing spoilage and deterioration. This not only reduces waste but also allows for wider distribution and longer storage periods.

- Enhanced brand image: Premium packaging materials convey a sense of quality and value to consumers. By investing in top-notch materials, beverage brands can create a positive impression and differentiate themselves from competitors, ultimately leading to increased customer loyalty and sales.

Factors to Consider in Material Selection

To ensure optimal beverage packaging, we must carefully consider various factors in material selection. When choosing the right materials for beverage packaging, cost considerations and durability factors are key considerations.

In terms of cost, it is important to strike a balance between the price of the materials and the value they provide. While it may be tempting to opt for cheaper materials to reduce costs, it is crucial to evaluate the long-term impact on the product’s quality and customer satisfaction. Investing in top-notch materials that offer durability can result in fewer product failures, reduced maintenance, and improved customer experience.

To help guide the material selection process, consider the following factors:

| Cost Considerations | Durability Factors |

|---|---|

| Material Price | Strength |

| Production Costs | Resistance |

| Maintenance Costs | Shelf Life |

Top Materials for Juice Packaging

We recommend using high-quality materials for juice packaging to ensure optimal product protection and customer satisfaction. When it comes to juice packaging, there are several top materials that offer both sustainability and innovative designs.

- Plant-based bioplastics: These materials are derived from renewable resources, such as corn or sugarcane, and have a lower carbon footprint compared to traditional plastics. They’re also compostable, reducing waste and environmental impact.

- Recycled paperboard: Made from recycled paper fibers, this material isn’t only eco-friendly but also provides excellent structural integrity and moisture resistance. It can be easily customized with vibrant designs and graphics, enhancing the shelf appeal of the juice products.

- Glass: Although glass isn’t as lightweight as other materials, it’s 100% recyclable and preserves the taste and freshness of juices. Glass bottles can be reused or recycled, making them a sustainable choice for juice packaging.

Sustainable Options for Beverage Packaging

For sustainable beverage packaging, we prioritize the use of environmentally friendly materials. In today’s world where consumers are increasingly conscious about the impact of their choices on the environment, it is imperative for beverage companies to offer recyclable alternatives and eco-friendly packaging options. By choosing materials that can be easily recycled, we can minimize waste and contribute to a circular economy.

One popular sustainable option is the use of plant-based plastics, such as PLA (polylactic acid), which are derived from renewable resources like cornstarch or sugarcane. These materials are biodegradable and reduce the reliance on fossil fuels. Additionally, paper-based packaging made from responsibly sourced, certified sustainable forest products is another eco-friendly choice. These materials can be recycled multiple times and have lower carbon footprints compared to traditional packaging materials.

To further illustrate the sustainable options available for beverage packaging, here is a table showcasing three examples:

| Sustainable Material | Features | Benefits |

|---|---|---|

| Plant-based plastics | Biodegradable, derived from renewable resources | Reduces reliance on fossil fuels |

| Paper-based packaging | Recyclable, sourced from sustainable forests | Lowers carbon footprints |

| Glass bottles | Infinitely recyclable, durable | Reduces waste and energy consumption |

Frequently Asked Questions

What Are the Potential Risks or Drawbacks of Using Low-Quality Materials in Beverage Packaging?

Using low-quality materials in beverage packaging can lead to potential risks and drawbacks. It can negatively impact product quality, causing customer dissatisfaction. Opting for top-notch materials ensures a better overall experience for consumers.

How Can Using Top-Notch Packaging Materials Enhance the Shelf Life of Beverages?

Using top-notch packaging materials enhances freshness and ensures product safety, ultimately extending the shelf life of beverages. By incorporating advanced technologies and superior materials, we can guarantee the highest quality and satisfaction for our customers.

Are There Any Specific Regulations or Standards That Dictate the Use of High-Quality Materials in Beverage Packaging?

Regulations and standards exist to ensure the use of high-quality materials in beverage packaging. These guidelines aim to maintain product safety, quality, and integrity, which ultimately benefits both consumers and manufacturers.

What Are Some Innovative Materials That Are Being Utilized in the Beverage Packaging Industry?

Innovative materials are revolutionizing the beverage packaging industry. We are seeing sustainable solutions like biodegradable plastics, plant-based materials, and recyclable packaging gaining traction. These advancements ensure top-notch quality while minimizing environmental impact.

Can the Use of Sustainable Packaging Materials Have a Positive Impact on a Brand’s Image and Customer Perception?

Using sustainable packaging materials can greatly enhance a brand’s reputation and customer perception. Studies show that 70% of consumers are willing to pay more for products packaged in eco-friendly materials, highlighting the positive impact it can have on a brand’s image.

Conclusion

In conclusion, opting for top-notch materials in beverage packaging is crucial for ensuring product quality and customer satisfaction. Using high-quality materials offers numerous benefits, such as enhanced product protection, improved shelf life, and increased brand value.

Additionally, selecting the right materials for packaging is essential, considering factors like durability, compatibility, and sustainability. Interestingly, a study found that 85% of consumers are willing to pay a premium for products packaged in sustainable materials, highlighting the growing importance of eco-friendly options in the beverage industry.

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.

Juice Manufacturing Process

Why Is Proper Temperature Crucial for Beverage Storage?

Temperature is the vital factor at the core of our mission to provide you with the ideal drink experience.

In this article, we delve into the importance of maintaining proper temperature for beverage storage. From the ideal range for juice storage to the impact on quality and prevention of spoilage, we explore the technicalities and best practices for temperature control.

Join us on this journey to discover why temperature is the key to unlocking the best flavors in your favorite beverages.

Key Takeaways

- The ideal temperature range for juice storage is between 32 and 40 degrees Fahrenheit to preserve its nutritional value, taste, and sensory characteristics.

- Temperature fluctuations can negatively impact enzymatic reactions in juice, leading to changes in taste, color, and nutritional value.

- Consistently maintaining the proper temperature for beverage storage is essential to prevent spoilage and ensure the safety and quality of the juice.

- Temperature monitoring, refrigeration systems, and regular maintenance are important methods for controlling and maintaining optimal temperature conditions for juice storage.

Ideal Temperature Range for Juice Storage

The ideal temperature range for juice storage is between 32 and 40 degrees Fahrenheit. Maintaining the proper temperature is crucial for preserving the quality, safety, and freshness of the juice.

Juice storage requirements are directly influenced by temperature, as fluctuations can have significant effects on juice safety. Cold temperatures help inhibit the growth of bacteria and other microorganisms, reducing the risk of spoilage and potential health hazards.

Additionally, storing juice within the recommended temperature range helps preserve its nutritional value, taste, and overall sensory characteristics. Temperature control is especially important for establishments that prioritize serving others, as it ensures that customers receive a safe and enjoyable beverage experience.

Impact of Temperature on Juice Quality

Maintaining the proper temperature range for juice storage impacts the quality and freshness of the beverage. Temperature fluctuation can have a significant effect on the enzymatic reactions in juice, which can ultimately lead to changes in taste, color, and nutritional value.

Enzymes are responsible for various chemical reactions in juice, such as the breakdown of sugars and the conversion of certain compounds into aroma and flavor components. When exposed to temperature fluctuations, these enzymatic reactions can become unstable, leading to the degradation of important compounds and the development of off-flavors.

Additionally, high temperatures can accelerate the growth of microorganisms, further compromising the quality and safety of the juice. Therefore, it’s crucial to maintain a consistent temperature during juice storage to ensure optimal quality and minimize the risk of spoilage.

In the following section, we’ll explore the role of temperature in preventing spoilage and ensuring the longevity of juice products.

The Role of Temperature in Preventing Spoilage

To prevent spoilage, it’s essential to consistently maintain the proper temperature for beverage storage. Proper temperature control plays a crucial role in preventing contamination and inhibiting microbial growth, ensuring that beverages remain safe and of high quality.

When beverages are stored at temperatures outside of the recommended range, harmful bacteria and other microorganisms can multiply rapidly, leading to spoilage and potential health risks for consumers. By maintaining the appropriate temperature, we can effectively slow down the growth of these microorganisms, extending the shelf life of beverages and preserving their freshness.

Temperature control methods for juice storage, which will be discussed in the subsequent section, are vital in achieving these goals and ensuring that beverages are served at their best quality.

Temperature Control Methods for Juice Storage

For juice storage, we rely on specific temperature control methods.

Temperature monitoring is essential to ensure that the juice is stored at the correct temperature to maintain its quality and extend its shelf life. One commonly used method is the use of temperature sensors or probes that are placed inside the storage area. These sensors continuously monitor the temperature and provide real-time data to ensure that it stays within the desired range.

Temperature regulation is achieved through the use of refrigeration systems or climate control devices, which adjust the temperature as needed to maintain optimal conditions. These systems are designed to provide a stable and controlled environment for juice storage, preventing temperature fluctuations that could lead to spoilage.

Best Practices for Maintaining Optimal Juice Temperature

We prioritize regular temperature checks to ensure that we maintain the optimal temperature for storing juice. Temperature regulation techniques play a vital role in preserving the freshness and quality of juice.

To maintain the ideal juice storage temperature, it’s essential to follow specific guidelines. Firstly, the recommended temperature for storing juice is between 32°F and 40°F (0°C and 4°C). This range prevents bacterial growth and helps retain the flavor and nutritional value of the juice.

Secondly, it’s crucial to store juice in a refrigerated environment to maintain its freshness. Additionally, regularly cleaning and maintaining the refrigeration units ensures proper temperature control.

Frequently Asked Questions

What Are the Potential Health Risks Associated With Storing Juice at Improper Temperatures?

Potential health risks of storing juice at improper temperatures include bacterial growth, spoilage, and the formation of harmful toxins. Proper temperature is crucial to prevent these risks and ensure the safety and quality of the beverage.

Are There Any Specific Types of Juice That Are More Sensitive to Temperature Changes?

Specific juice types exhibit varying degrees of temperature sensitivity, making proper temperature crucial for their storage. Understanding these variations allows us to serve others effectively by preserving the quality and taste of each beverage.

Can Fluctuations in Temperature Affect the Nutritional Content of Juice?

Fluctuations in temperature can have a significant impact on the nutritional content, flavor profile, and texture of juice. It is crucial to maintain proper temperature to preserve the quality of juice and ensure an enjoyable drinking experience.

How Does Temperature Impact the Shelf Life of Juice?

Temperature greatly affects the shelf life of juice. Fluctuations can break down nutrients and lead to spoilage. To ensure freshness, store juice at the recommended temperature. Proper temperature is crucial for preserving the quality and taste of fruit juices.

Are There Any Specific Storage Containers or Packaging Materials That Help Maintain Optimal Juice Temperature?

Insulated containers and cooling sleeves are specific storage solutions to maintain optimal beverage temperature. They prevent heat transfer and keep beverages cool for longer periods, ensuring freshness and taste.

Conclusion

In conclusion, maintaining the proper temperature for beverage storage is crucial for preserving the quality and preventing spoilage.

It may seem like a trivial detail, but failing to control temperature can lead to disastrous consequences. Just imagine the irony of investing in high-quality juice only to have it go bad due to negligence in temperature control.

So let’s not underestimate the impact of temperature and ensure we follow the best practices to keep our beverages at their optimal temperature.

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.

Juice Manufacturing Process

Why Does Packaging Affect Shelf Life of Beverages?

The foundation of every drink is its packaging, serving as a protector of freshness and taste.

We, the curious minds, delve into the realm of packaging to uncover its impact on the shelf life of our beloved beverages.

Through our analytical lenses, we explore the types of juice packaging materials, the influence of oxygen and light, the role of temperature, and the importance of proper sealing techniques.

Join us on this journey towards serving you the knowledge you seek.

Key Takeaways

- Packaging materials with low oxygen permeability can extend the shelf life of beverages by reducing oxygen exposure and preventing chemical reactions that degrade quality and taste.

- Light exposure can lead to photooxidation and degradation of sensory and nutritional properties in beverages. Proper packaging materials should provide adequate light protection to minimize these effects.

- Consistent temperature control is crucial for preventing microbial growth and spoilage. Proper cold chain management and heat treatment techniques like pasteurization help preserve freshness and nutritional value.

- Proper sealing and packaging techniques are essential for preserving the integrity and freshness of beverages. Effective packaging techniques protect against external elements such as light exposure, flavor degradation, and nutrient loss.

Types of Juice Packaging Materials

When considering the shelf life of beverages, it’s important to explore the different types of juice packaging materials that can significantly impact their overall quality and longevity.

One key aspect to consider is the use of recyclable options, which not only aligns with sustainability goals but also ensures that the packaging material can be reused or repurposed, reducing waste.

Additionally, the cost effectiveness of packaging materials is a crucial factor that affects the shelf life of beverages. By opting for cost-effective materials, beverage manufacturers can reduce their production costs and pass on the savings to consumers.

It’s vital to select packaging materials that strike a balance between quality, longevity, recyclability, and cost effectiveness to ensure that beverages remain fresh and appealing for an extended period.

Impact of Oxygen Exposure on Juice Shelf Life

To further explore how packaging affects the shelf life of beverages, let’s now delve into the impact of oxygen exposure on the longevity of juice.

Oxygen absorption in juice can lead to the oxidation process, which can significantly reduce its shelf life. Here are three key points to consider:

- Oxygen absorption: When juice comes into contact with oxygen, it can lead to chemical reactions that degrade its quality and taste.

- Oxidation process: Oxygen reacts with the natural compounds present in juice, causing them to break down and undergo oxidation. This can result in off-flavors, discoloration, and nutrient loss.

- Shelf life: The rate at which oxygen permeates the packaging material and enters the juice determines its shelf life. Packaging materials with low oxygen permeability can help minimize oxygen exposure and extend the juice’s shelf life.

Understanding the impact of oxygen exposure on juice shelf life is crucial for ensuring that consumers are served with fresh and high-quality beverages.

Influence of Light on Juice Quality and Shelf Life

Light exposure plays a significant role in determining the quality and shelf life of juice. When juice is exposed to light, it undergoes a process called photooxidation, which leads to the degradation of its sensory and nutritional properties. This is primarily due to the interaction between the light and the juice’s components, such as vitamins, pigments, and antioxidants.

Light exposure can cause the degradation of vitamins, such as vitamin C, leading to a loss of nutritional value. Additionally, pigments in the juice, such as chlorophyll and carotenoids, can undergo photochemical reactions, resulting in color changes and off-flavors. Furthermore, light exposure can lead to the breakdown of antioxidants, reducing the juice’s ability to protect against oxidation.

To mitigate the negative effects of light exposure, it’s essential to use packaging materials that provide adequate light protection, such as opaque or tinted containers. Proper packaging can help maintain the quality and extend the shelf life of juice by minimizing juice oxidation caused by light exposure.

The Role of Temperature in Juice Packaging and Storage

Managing temperature is crucial for ensuring the quality and shelf life of juice during packaging and storage. The impact of temperature on beverage quality can’t be overstated. Here are three key points to consider when it comes to juice storage techniques and temperature:

- Temperature control: Maintaining a consistent temperature throughout the packaging and storage process is essential. Fluctuations in temperature can lead to microbial growth and spoilage, affecting the taste and safety of the juice.

- Cold chain management: Proper cold chain management is crucial to preserve the freshness and nutritional value of the juice. This involves keeping the juice at a controlled temperature from production to distribution to prevent degradation.

- Pasteurization: Heat treatment, such as pasteurization, is often used to kill harmful microorganisms in juice. It’s important to follow the recommended temperature and time parameters to ensure effective pasteurization without compromising the juice’s quality.

Understanding and implementing proper temperature control techniques is vital for maintaining the integrity of the juice.

Now, let’s delve into the importance of proper sealing and packaging techniques.

Importance of Proper Sealing and Packaging Techniques

Now let’s delve into the significance of ensuring proper sealing and packaging techniques for maintaining the quality and shelf life of beverages.

Proper sealing and packaging techniques play a crucial role in preserving the integrity and freshness of beverages.

When beverages are improperly sealed or packaged, they’re exposed to external contaminants such as air, moisture, and light, which can accelerate the degradation process.

Proper sealing prevents air and moisture from seeping into the packaging, reducing the risk of microbial growth and oxidation.

Additionally, effective packaging techniques, such as using high-quality materials and employing airtight seals, can protect beverages from light exposure, which can lead to flavor degradation and nutrient loss.

Frequently Asked Questions

Can the Type of Packaging Material Affect the Taste or Flavor of the Juice?

Yes, the type of packaging material can affect the taste or flavor of the juice. Different materials can leach chemicals into the beverage, altering its flavor profile. It is important to choose packaging that is compatible with the beverage to maintain its taste integrity.

How Does Exposure to Oxygen Impact the Nutritional Value of the Juice?

Exposure to oxygen significantly impacts the nutritional value of juice. Studies show that oxidation caused by oxygen can lead to a decrease in vitamins and antioxidants. Packaging plays a crucial role in preventing this oxidation and maintaining juice quality.

Can the Color of the Juice Be Affected by Exposure to Light?

Exposure to sunlight can impact the color of juice, causing it to change or fade. To prevent light exposure in juice packaging, opaque or dark-colored containers can be used to block out harmful rays and maintain the juice’s color.

Does the Temperature at Which Juice Is Stored Affect Its Shelf Life?

The shelf life of beverages can be affected by the storage temperature. Higher temperatures promote microbial growth, leading to spoilage. Proper temperature control is crucial to ensuring the longevity of packaged drinks.

Are There Any Specific Techniques or Methods for Ensuring Proper Sealing of Juice Packaging?

Proper sealing techniques and quality control measures are crucial for ensuring the longevity of beverage packaging. By implementing these methods, we can maintain the integrity of the packaging, thereby enhancing shelf life and customer satisfaction.

Conclusion

In conclusion, it’s imperative to understand that the choice of packaging for beverages plays a crucial role in determining their shelf life.

Factors such as oxygen exposure, light, temperature, and proper sealing techniques all contribute to the preservation of the product’s quality.

By carefully considering these aspects and utilizing appropriate packaging materials, producers can ensure that their beverages retain their freshness and appeal, delighting consumers with a euphoric sensory experience.

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.

-

Juice Tips and Tricks3 weeks ago

Juice Tips and Tricks3 weeks agoHow To Make Homemade Pickle Juice

-

Health Benefits of Juice1 month ago

Health Benefits of Juice1 month agoHow Much Bottled Lemon Juice Equals 1 Lemon

-

Juice Tips and Tricks1 week ago

Juice Tips and Tricks1 week agoHow Much Lemon Juice Is Equal To Half A Lemon

-

Juice Tips and Tricks2 weeks ago

Juice Tips and Tricks2 weeks agoHow Much Lemon Juice Concentrate Equals One Lemon

-

Popular Juice Brands3 months ago

Popular Juice Brands3 months ago10 Top-Rated Organic Juice Brands to Try

-

Popular Juice Brands3 months ago

Popular Juice Brands3 months ago9 Best No-Sugar-Added Popular Juice Brands

-

Juice Tips and Tricks2 days ago

Juice Tips and Tricks2 days agoHow Long Can You Drink Orange Juice After The Expiration Date

-

Juice Tips and Tricks1 month ago

Juice Tips and Tricks1 month agoHow Long Does Lemon Juice Last After Expiration Date