Batch codes on juice bottles are your best tool to identify freshness and safety, especially during issues. They include manufacturing dates, sometimes represented as Julian or calendar dates, helping you determine if the product is fresh or stored too long. These codes also assist manufacturers in tracing affected batches during recalls or spoilage concerns. Understanding how to interpret these batch numbers guarantees you make informed, safe choices and stay protected—keep going to discover how to decode them effectively.

Key Takeaways

- Batch codes identify production dates, helping consumers determine juice freshness and avoid spoiled or over-fermented products.

- Clear batch coding allows quick traceability during recalls or quality issues, ensuring consumer safety.

- Understanding date formats (Julian or calendar) enables consumers to assess product age accurately.

- Proper batch codes assist manufacturers in controlling fermentation and flavor stability throughout shelf life.

- Recognizing batch codes helps consumers make informed choices and take swift action if issues arise.

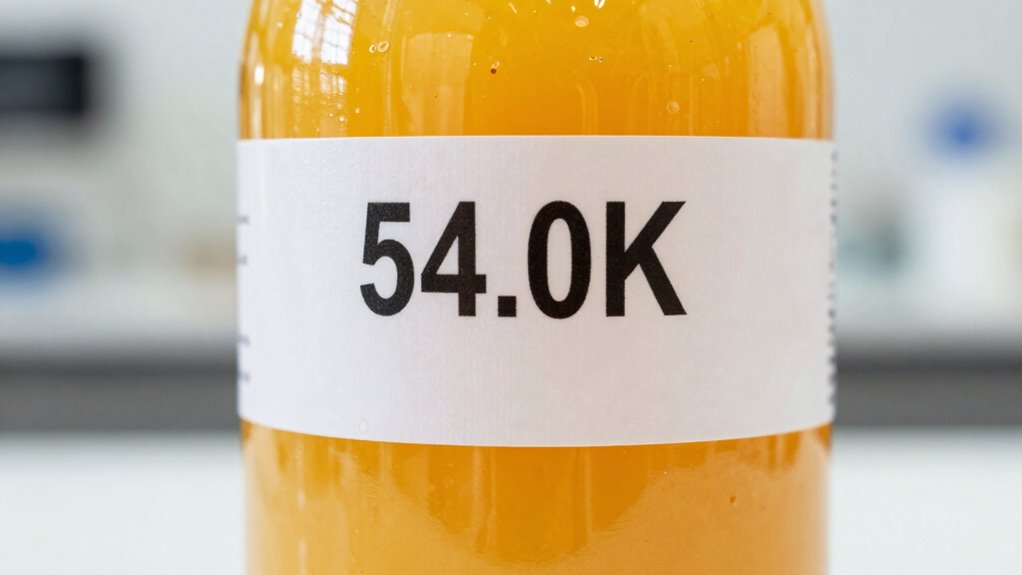

Understanding date coding for juice is essential to guarantee you’re consuming fresh and safe products. When you pay attention to batch codes and expiration dates, you gain control over the quality and safety of the juice you enjoy. Proper date coding helps manufacturers and consumers alike monitor fermentation control, ensuring that the juice remains within safe fermentation levels. It also plays a key role in maintaining flavor stability, which directly impacts your experience with the product. By knowing how to interpret these codes, you can avoid purchasing or consuming juice that might have undergone undesirable fermentation or flavor changes, preserving the intended taste and quality. Recognizing accurate batch coding can also help you better understand product freshness and safety. Batch codes are more than just numbers; they serve as a detailed record of the production process. They often include information about the manufacturing date, time, and sometimes even specific production lines. Recognizing these codes allows you to identify whether the juice is fresh or if it’s been stored too long, risking spoilage. For manufacturers, accurate batch codes enable better fermentation control—preventing over-fermentation that could lead to off-flavors or unsafe products. This control is essential because uncontrolled fermentation can cause spoilage, compromise safety, and affect flavor stability, all of which diminish your enjoyment and trust in the product. When you look at juice labels, understanding the date coding system helps you make informed decisions. For example, some companies use Julian dates, which represent the day of the year, while others use standard calendar dates. Familiarity with these systems ensures that you can quickly assess whether a product is still within its prime freshness window. This is especially important for products with a shorter shelf life or those that are more sensitive to temperature fluctuations during storage. By choosing juice with a clear and recent date code, you reduce the risk of consuming a product that has lost flavor stability or undergone undesirable fermentation. Furthermore, batch codes are indispensable during recalls or quality issues. If a manufacturer detects a problem with a certain batch, they can trace and isolate affected products using these codes. As a consumer, this information helps you understand if your purchased juice might be impacted, and it empowers you to take appropriate action. Overall, understanding date coding for juice is more than a simple habit; it’s an essential part of ensuring you enjoy safe, flavorful, and high-quality juice every time. By paying close attention to batch codes and expiration dates, you bring control into your hands and help safeguard your health and taste experience.

Frequently Asked Questions

How Can I Decipher Different Juice Batch Code Formats?

You can decipher different juice batch code formats by closely examining canning dates and packaging labels. Look for numbers or letters indicating manufacturing dates, often formatted as MM/DD/YYYY or DD/MM/YYYY, and note any batch identifiers. Compare these with the packaging labels, which might include expiration dates or lot numbers. If formats differ, consult the manufacturer’s guidelines or website, as they usually provide decoding instructions for their specific batch code system.

Are There Industry Standards for Date Coding in Juice Manufacturing?

Yes, there are industry standards for date coding in juice manufacturing. You need to follow industry compliance and adhere to labeling regulations, which often specify format, placement, and clarity of date codes. These standards help ensure traceability and quality control. By using recognized date coding practices, you can easily verify product freshness, meet regulatory requirements, and streamline your recall processes if necessary.

What Should I Do if the Batch Code Is Unreadable?

When faced with unreadable batch code symbols, don’t throw in the towel. Instead, document any decoding challenges and contact your supplier or manufacturer for clarification. They often keep records linked to production dates, helping you trace the batch. Keep a detailed log of your efforts, as this can save you time and headaches if issues arise. Clear communication is key; it’s better to ask than guess.

How Often Do Juice Batch Codes Change During Production?

You should expect juice batch codes to change regularly during production, often daily or per batch, to track batch history effectively. These updates are reflected on juice packaging labels, helping trace issues back to specific production runs. Staying familiar with batch code history enables quick identification of contaminated or problematic batches, ensuring quality control. Regularly check labels for new codes to stay informed and protect your consumers.

Can Batch Codes Indicate Quality or Freshness?

Batch codes alone don’t guarantee juice quality or freshness, but they can help you assess it. Don’t rely solely on label accuracy; instead, use batch codes to track production dates and identify recent batches. This boosts your consumer awareness, allowing you to make informed choices. While batch codes aren’t perfect indicators, they’re valuable tools that, when combined with your judgment, help you select fresher, higher-quality juice.

Conclusion

So, next time you’re squeezing that perfectly ripe juice, remember those batch codes are your secret superheroes—fighting off spoiled surprises and dodgy batches. They’re like tiny detectives hiding in the label, ready to save your taste buds from a tragic, tangless fate. Keep an eye on those numbers, and you’ll dodge the juice drama like a pro. After all, a little date code vigilance turns you into the true hero of your fruity adventures.