Juice Manufacturing Process

9 Best Steps in Industrial Juice Manufacturing Process

Have you ever stopped to think about how juice is made while enjoying a refreshing glass?

Well, in this article, we’re going to take you through the 9 best steps in the industrial juice manufacturing process. Whether you’re just starting out or looking to optimize your current production, understanding these key stages will help you create high-quality juice efficiently. We’ll also share some essential tips for juice manufacturing to ensure you avoid common pitfalls and maintain consistency in flavor, safety, and shelf life. Let’s dive into the process step by step!

From harvesting and selecting the raw fruits to packaging and labeling the final product, we’ll give you a practical and knowledgeable insight into how your favorite juices are made.

So, sit back, relax, and let’s dive into the world of industrial juice manufacturing.

Key Takeaways

- The process of industrial juice manufacturing involves carefully selecting and harvesting raw fruits, ensuring they are ripe and fresh.

- Cleaning and sanitizing the fruits is crucial to prevent contamination and remove dirt and contaminants.

- Juice extraction techniques such as mechanical and enzymatic methods are used to extract the juice from the fruits while retaining optimal flavor and nutrients.

- Filtering, clarifying, and pasteurizing the juice are essential steps to ensure a smooth, clear, and safe final product with an extended shelf life.

Harvesting and Selecting Raw Fruits

In our industrial juice manufacturing process, we begin by carefully selecting and harvesting the raw fruits that will become the foundation of our delicious beverages. We understand the importance of using high-quality fruits to create the best possible juices for our customers. Our team of experts meticulously examines each fruit, ensuring that only the ripest and freshest ones are chosen. We take pride in sourcing our fruits from trusted farmers who share our commitment to quality. By handpicking the fruits, we can guarantee that only the best ones make it into our juicing process.

This attention to detail allows us to create juices that are bursting with flavor and packed with nutrients. As we move forward, the next crucial step in our process is cleaning and sanitizing the fruits to ensure the highest standards of hygiene and safety.

Cleaning and Sanitizing Fruits

When it comes to manufacturing juice, ensuring fruit hygiene is of utmost importance. To achieve this, effective cleaning techniques must be employed to remove any dirt, pesticides, or other contaminants from the fruits.

Additionally, sanitizing methods should be implemented to ensure the safety of the final product.

Fruit Hygiene Importance

To ensure the safety and quality of our industrial juice products, we prioritize the thorough cleaning and sanitization of fruits.

Fruit hygiene is of utmost importance in our manufacturing process, as it helps prevent contamination and ensures the freshness of our juices.

Before processing, all fruits are carefully inspected to remove any damaged or spoiled pieces. They’re then washed using a combination of water and food-grade sanitizers to eliminate any potential pathogens or residues.

This step is crucial in maintaining the integrity of our products and meeting the highest hygiene standards. Additionally, our cleaning protocols are constantly reviewed and updated to stay in line with industry best practices.

Effective Cleaning Techniques

We prioritize effective cleaning techniques, using a combination of water and food-grade sanitizers, to ensure the safety and quality of our industrial juice products. To achieve this, we follow a rigorous cleaning process that involves the following steps:

- Pre-washing: We begin by rinsing the fruits thoroughly with water to remove any visible dirt or debris.

- Sanitizing: After pre-washing, we use food-grade sanitizers to kill any remaining bacteria or pathogens on the fruit’s surface.

These cleaning techniques are crucial in eliminating potential contaminants and ensuring that our industrial juice products meet the highest standards of hygiene.

Sanitizing Methods for Safety

After pre-washing and removing visible dirt or debris from the fruits, we proceed to sanitize them using food-grade sanitizers.

Sanitizing the fruits is a crucial step in ensuring the safety of the juice manufacturing process. Food-grade sanitizers effectively eliminate harmful bacteria and pathogens that may be present on the fruit’s surface.

To sanitize the fruits, we immerse them in a solution of food-grade sanitizer for a specific period of time. This allows the sanitizer to penetrate and eliminate any remaining contaminants. It’s important to follow the manufacturer’s instructions for dilution and contact time to ensure maximum effectiveness.

Once the fruits have been properly sanitized, we can confidently move on to the next step of extracting juice from them.

Extracting Juice From Fruits

When extracting juice from fruits, our team utilizes a combination of mechanical and enzymatic methods to ensure optimal flavor and nutrient retention. This allows us to provide our customers with the highest quality juice possible.

Here are the steps we follow to extract juice from fruits:

- Mechanical extraction:

- Crushing and pressing: We use specialized machinery to crush the fruits and extract the juice by pressing them.

- Centrifugal force: By spinning the crushed fruits rapidly, we separate the juice from the pulp.

- Enzymatic extraction:

- Enzyme treatment: We add enzymes to the crushed fruits to break down the cell walls and release the juice.

- Maceration: The fruits are soaked in enzymes to further enhance the extraction process.

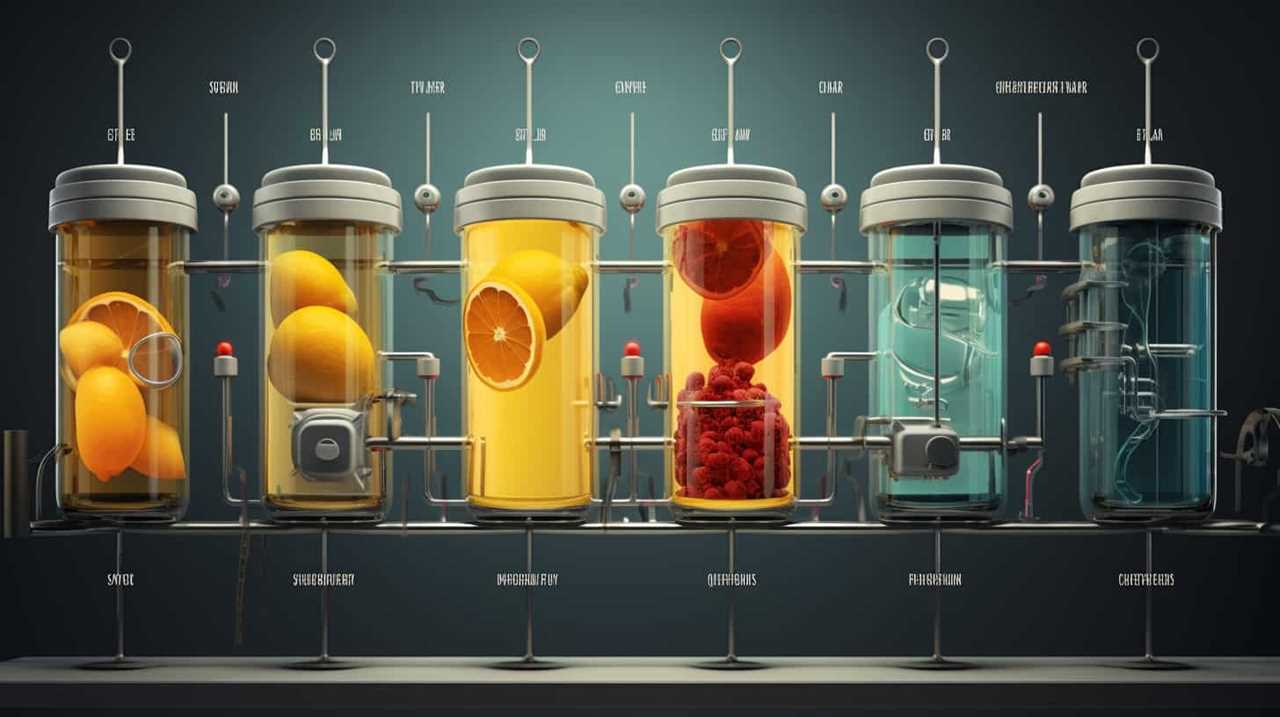

Filtering and Clarifying the Juice

To filter and clarify the juice, our team utilizes a combination of methods to remove any impurities and ensure a smooth and clear final product.

First, the juice is passed through a coarse filter to remove larger particles such as pulp and seeds.

Next, it undergoes a process called clarification, where enzymes or natural settling agents are added to help separate any remaining solids from the liquid.

This mixture is then allowed to settle, and the clear juice is carefully decanted or siphoned off, leaving behind any sediment.

Finally, the juice is passed through a fine filter to remove any microscopic impurities and ensure its purity.

Pasteurizing the Juice for Safety

To ensure the safety of our juice, we employ the process of pasteurization. This essential step involves heating the juice to a specific temperature for a predetermined amount of time to kill harmful bacteria and pathogens.

Here’s why pasteurization is crucial in the manufacturing of industrial juice:

- It eliminates harmful microorganisms: Pasteurization effectively destroys bacteria, yeast, and molds that may be present in the juice, ensuring it’s safe for consumption.

- It extends shelf life: By eliminating spoilage-causing organisms, pasteurization helps prevent the juice from deteriorating quickly, allowing it to have a longer shelf life. This reduces waste and increases profitability for juice manufacturers.

- It preserves nutritional value: Pasteurization minimally affects the juice’s nutritional content, allowing consumers to enjoy the health benefits of the fruits or vegetables used.

With the juice now safely pasteurized, we can move on to the next step of adding preservatives and flavorings to enhance taste and prolong shelf life.

Adding Preservatives and Flavorings

When it comes to adding preservatives and flavorings in the industrial juice manufacturing process, there are several important points to consider.

Firstly, the types of preservatives available, such as natural or artificial options, can impact the shelf life and safety of the juice.

Secondly, the choice of flavorings, whether it’s natural extracts or artificial additives, can greatly influence the taste and appeal of the final product.

Lastly, it’s crucial to understand the potential effect of these additives on the overall quality of the juice, ensuring that they enhance rather than compromise its nutritional value.

Types of Preservatives

We add preservatives and flavorings to our industrial juice manufacturing process. Preservatives are substances that help extend the shelf life of our juice products, ensuring that they remain fresh and safe for consumption. There are different types of preservatives that we use, including:

- Natural preservatives:

- Citric acid: Derived from citrus fruits, it acts as an antioxidant and helps to inhibit the growth of bacteria and mold.

- Vitamin C: Also known as ascorbic acid, it not only acts as a preservative but also enhances the flavor and color of the juice.

- Synthetic preservatives:

- Sodium benzoate: Effective against yeast, bacteria, and mold, it’s commonly used in acidic juices.

- Potassium sorbate: It prevents the growth of yeast, mold, and fungi in various juice products.

Flavoring Options Available

Regularly, we incorporate various flavoring options into our industrial juice manufacturing process, along with the addition of preservatives. Our goal is to create a wide range of flavors that cater to the diverse preferences of our customers. We carefully select high-quality flavorings that are natural and free from any artificial additives. Some of the popular flavorings we use include fruit essences, extracts, and concentrates. These flavorings not only enhance the taste of the juice but also provide a vibrant and refreshing experience for the consumers.

We understand the importance of maintaining the integrity of the juice while adding flavorings, which is why we follow strict quality control measures throughout the manufacturing process. By carefully balancing the flavorings and preservatives, we ensure that the final product meets the highest standards of taste and quality.

Transitioning into the subsequent section about the effect on juice quality, it’s essential to understand how the addition of flavorings and preservatives impacts the overall quality of the juice.

Effect on Juice Quality

The addition of preservatives and flavorings significantly influences the overall quality of the juice. When it comes to preserving the freshness and extending the shelf life of the juice, certain preservatives are added. These include natural preservatives like citric acid and ascorbic acid, as well as artificial preservatives such as sodium benzoate and potassium sorbate.

On the other hand, flavorings are added to enhance the taste and aroma of the juice. These can be natural flavors extracted from fruits or artificial flavors created in a laboratory. While preservatives help maintain the juice’s quality over time, flavorings ensure a delightful and enjoyable drinking experience.

Both preservatives and flavorings must be carefully chosen and properly balanced to create a high-quality juice that satisfies the taste buds of consumers.

As we move on to the next section, we’ll explore the crucial steps in packaging and labeling the juice.

Packaging and Labeling the Juice

During the industrial juice manufacturing process, one important step is to carefully package and label the juice. Proper packaging and labeling ensure that the juice remains fresh and safe for consumption while also providing important information to consumers. To grab the attention of our audience, let’s take a look at a table that highlights the key elements of packaging and labeling:

| Packaging | Labeling | Benefits |

|---|---|---|

| Airtight containers | Clear and concise information | Preserves freshness |

| Tamper-evident seals | Nutritional facts and ingredients | Ensures product integrity |

| Protective packaging materials | Allergen warnings | Prevents damage during transit |

| Eco-friendly packaging options | Expiration date | Appeals to environmentally conscious consumers |

Quality Control and Testing

To ensure the highest quality of juice production, we prioritize rigorous quality control and testing throughout our manufacturing process.

Our commitment to quality starts with carefully selecting the finest fruits and ingredients. We conduct thorough inspections to ensure that only the best raw materials are used.

In addition, we’ve implemented advanced testing methods to analyze the juice at various stages of production. This includes testing for flavor, color, consistency, and nutritional value.

Our dedicated team of experts meticulously monitors every aspect of the manufacturing process, from the initial blending to the final packaging.

We also conduct regular audits to ensure that our facilities and equipment meet the highest standards of cleanliness and safety.

Storage and Distribution of the Juice

How do we ensure the proper storage and distribution of our carefully crafted juice? It is crucial to maintain the quality and freshness of our juice throughout the storage and distribution process. We follow strict guidelines to ensure that our juice reaches customers in the best possible condition. Here is a table outlining our storage and distribution practices:

| Storage | Distribution |

|---|---|

| – Temperature-controlled warehouses | – Efficient logistics system |

| – Regular quality checks | – Reliable transportation |

| – Proper labeling and packaging | – Timely delivery |

| – FIFO (First In, First Out) method | – Collaboration with trusted retailers |

Frequently Asked Questions

What Are the Various Sanitation Methods Used in Cleaning and Sanitizing Fruits for Juice Manufacturing?

For cleaning and sanitizing fruits in juice manufacturing, we use various sanitation methods. These methods ensure that the fruits are free from harmful bacteria and contaminants, maintaining high standards of cleanliness and safety.

Are There Any Specific Fruits That Are More Challenging to Extract Juice From?

Yes, there are certain fruits that can pose challenges in extracting juice. However, with our expertise and efficient processes, we have developed effective techniques to overcome these challenges and ensure high-quality juice production.

How Does the Filtering and Clarifying Process Contribute to the Overall Quality of the Juice?

Filtering and clarifying the juice is crucial for ensuring its overall quality. These processes remove impurities, sediment, and any remaining solids, resulting in a clear and pure juice that meets the highest standards of taste and safety.

What Temperature and Duration Are Typically Used During the Pasteurization Process to Ensure the Safety of the Juice?

To ensure the safety of the juice, we typically use high temperatures and a specific duration during the pasteurization process. This step acts as a protective shield, eliminating harmful bacteria and preserving the juice’s freshness.

What Factors Are Considered When Selecting Preservatives and Flavorings for Industrial Juice Manufacturing?

When selecting preservatives and flavorings for industrial juice manufacturing, we consider factors such as safety, taste, shelf life, and customer preferences. It’s important to choose ingredients that meet regulatory standards and enhance the overall quality of the product.

Conclusion

In conclusion, the industrial juice manufacturing process is a well-oiled machine that ensures the highest quality and safety standards. From carefully selecting the freshest fruits to the precise filtering and pasteurization techniques, every step is carried out with meticulous attention.

The addition of preservatives and flavorings further enhances the taste and shelf life of the juice. With rigorous quality control and testing, consumers can trust that they’re getting the best possible product.

From start to finish, the process is a testament to the practicality and expertise of the industry.

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.

Juice Manufacturing Process

What Are Innovative Ways for Storing and Packing Liquids?

We have all faced the challenge of finding the most effective way to store and transport liquids without compromising freshness and convenience. Luckily, after extensive research, we have found some revolutionary solutions that will simplify your life. Among the top liquid storage solutions we have found are innovative, leak-proof containers that have airtight seals, guaranteeing that your liquids remain fresh for extended periods of time. Furthermore, many of these containers are stackable and designed to save space, making them ideal for transportation and storage in small areas. Thanks to these advancements, you no longer have to choose between convenience and freshness!

From biodegradable juice pouches to airtight glass bottles, flexible silicone containers to vacuum-sealed juice bags, and stackable juice cartons, there’s something for everyone.

Get ready to revolutionize your liquid storage game with these game-changing ideas!

Key Takeaways

- Biodegradable and compostable options: There are innovative options available for packing liquids such as juice pouches made from plant-based materials and compostable pouches that reduce waste. These options are lightweight, portable, leak-proof, and easily sealed.

- Glass bottle solutions: Airtight glass bottles are spill-proof and transparent, making it easy to identify the liquid inside. They are also easy to clean and maintain, environmentally friendly, and durable, providing a versatile packaging solution.

- Silicone containers: Reusable silicone pouches and collapsible drink containers are durable and environmentally friendly. They are also convenient and space-saving, providing a practical and sustainable solution for storing and packing liquids.

- Vacuum-sealed bags: Vacuum-sealed juice bags remove excess air, ensuring longer freshness. These bags are space-saving, lightweight, leak-proof, and easy to carry. However, they may not be suitable for carbonated beverages.

Biodegradable Juice Pouches

One innovative way for storing and packing liquids is by using biodegradable juice pouches. These compostable liquid containers are made from plant-based materials that break down naturally over time, reducing waste and minimizing the impact on the environment. Not only are they sustainable beverage packaging options, but they also provide a practical solution for on-the-go lifestyles.

Biodegradable juice pouches are lightweight and portable, making them ideal for carrying liquids such as juice, water, or other beverages. They’re leak-proof and can be easily sealed, ensuring that the liquids stay fresh and secure.

Transitioning to the next section, another option for storing and packing liquids is using airtight glass bottles.

Airtight Glass Bottles

We have found that a popular option for storing and packing liquids innovatively is using airtight glass bottles. These reusable mason jars aren’t only environmentally friendly, but they also offer several benefits.

First and foremost, airtight glass bottles provide a spill-proof solution, ensuring that your liquids are securely sealed and won’t leak during transportation. This is especially important when packing liquids such as oils, sauces, or beverages.

Additionally, glass bottles are transparent, allowing you to easily identify the contents without having to open them. They’re also easy to clean and maintain, making them a convenient choice for storing and serving liquids.

With their durability and versatility, airtight glass bottles are an excellent option for anyone looking to store and pack liquids in an innovative and efficient manner.

Flexible Silicone Containers

To continue exploring innovative ways for storing and packing liquids, let’s now delve into the realm of flexible silicone containers. These containers offer a range of benefits, making them a popular choice for those seeking practical and eco-friendly solutions.

Here are some key advantages:

- Reusable silicone pouches: These pouches aren’t only durable but also environmentally friendly. They can be used repeatedly, reducing the need for single-use plastic bags and promoting sustainability.

- Collapsible drink containers: Perfect for those on the go, collapsible drink containers provide convenience and space-saving capabilities. They can easily be folded or rolled up when empty, making them ideal for travel or outdoor activities.

Flexible silicone containers provide a versatile and efficient way to store and transport liquids. Whether it’s reusable silicone pouches or collapsible drink containers, these innovative solutions cater to the needs of individuals who value practicality and sustainability.

Vacuum-Sealed Juice Bags

Moving on from flexible silicone containers, let’s now explore the innovative solution of vacuum-sealed juice bags. These reusable juice bladders are collapsible liquid containers that offer convenience and portability for storing and packing liquids, including juice. The vacuum-sealed design removes excess air, minimizing oxidation and preserving the freshness and flavor of the juice for longer periods.

To help you visualize the benefits of vacuum-sealed juice bags, here’s a comparison table:

| Advantages | Limitations |

|---|---|

| 1. Space-saving and lightweight | 1. Limited capacity |

| 2. Leak-proof and easy to carry | 2. Not suitable for carbonated beverages |

| 3. Versatile and can be used for various liquids | 3. Some bags may require a special dispenser |

Vacuum-sealed juice bags offer a practical and eco-friendly alternative to traditional juice containers. Their flexibility and compactness make them ideal for travel, outdoor activities, and even everyday use. So, the next time you’re looking for an innovative way to store and pack your favorite juices, consider using vacuum-sealed juice bags.

Stackable Juice Cartons

Continuing from our exploration of innovative ways for storing and packing liquids, let’s now delve into the convenience and practicality of stackable juice cartons.

- Stackable juice cartons are a great solution for those who want to save space in their refrigerator or pantry. With their unique design, these cartons can be easily stacked on top of each other, maximizing storage capacity.

- Reusable juice boxes are another option for those looking to reduce waste and save money. These boxes are made from durable materials and can be washed and reused multiple times, making them an eco-friendly choice.

- Collapsible juice containers offer the ultimate convenience for on-the-go individuals. These containers can be easily collapsed and stored away when not in use, saving precious space in backpacks or lunchboxes.

Frequently Asked Questions

Are There Any Health Concerns Associated With Using Biodegradable Juice Pouches?

Health concerns associated with biodegradable juice pouches include potential chemical leaching and contamination. It’s important to consider the environmental impact of these pouches as well, as they may not degrade as quickly as advertised.

Can Airtight Glass Bottles Be Used for Carbonated Beverages?

Airtight glass bottles are a great alternative to plastic for carbonated beverages. They provide a sturdy and eco-friendly option for storage. Other innovative ways include using biodegradable materials and exploring new packaging techniques.

How Durable Are Flexible Silicone Containers and Can They Withstand High Temperatures?

Flexible silicone containers are highly durable and can withstand high temperatures. They are a great option for storing and packing liquids, providing a versatile and efficient solution.

Are Vacuum-Sealed Juice Bags Suitable for Long-Term Storage of Liquids?

Vacuum-sealed juice bags provide an innovative solution for long-term liquid storage. They maintain freshness and prevent leakage, ensuring liquids stay safe and drinkable. Our team recommends these bags for efficient and convenient liquid packaging.

What Are the Advantages of Using Stackable Juice Cartons Compared to Other Storage Options?

The advantages of using stackable juice cartons for storing and packing liquids are that they are space-efficient, easy to stack, and can be securely sealed to prevent leaks and spills. Properly storing and packing liquids is crucial for maintaining freshness and preventing contamination.

Conclusion

Innovative ways for storing and packing liquids offer exciting solutions to the age-old problem of leaky containers.

Imagine a world where biodegradable juice pouches prevent spills and reduce waste.

Picture airtight glass bottles preserving the freshness of your favorite beverages.

Visualize flexible silicone containers that conform to any space, maximizing storage efficiency.

Envision vacuum-sealed juice bags that eliminate air and keep liquids secure.

And finally, think of stackable juice cartons that optimize space in your fridge.

These innovative options revolutionize liquid storage and make life easier for all.

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.

Juice Manufacturing Process

Top Materials for Superior Beverage Packaging

As experts in beverage packaging, we understand the challenges that come with finding materials that provide top-notch performance.

You might be wondering, ‘Why should I care about the materials used in beverage packaging?’ Well, let us assure you, the right materials can make all the difference in preserving flavor, ensuring safety, and reducing environmental impact.

In this article, we will explore the top materials for beverage packaging, including glass, PET bottles, Tetra Pak cartons, aluminum cans, and biodegradable options.

Join us as we dive into the world of superior beverage packaging materials.

Key Takeaways

- Glass packaging offers durability and aesthetic appeal, but it is heavier and more fragile compared to other materials.

- PET bottles are versatile and convenient, lightweight, and highly recyclable.

- Tetra Pak cartons provide excellent protection and beverage preservation, are made from recyclable materials, and are lightweight and easy to handle.

- Aluminum cans are lightweight and portable, have an excellent barrier against light, oxygen, and moisture, and are highly recyclable.

Glass Packaging

When it comes to choosing the ideal material for beverage packaging, we prefer glass packaging for its durability and aesthetic appeal. Glass packaging offers numerous advantages in the beverage industry.

Firstly, glass is an inert material, meaning it doesn’t react with the contents of the beverage, ensuring the taste and quality remain unaffected.

Furthermore, glass packaging is fully recyclable and can be reused multiple times, making it a sustainable choice.

However, glass packaging does have its disadvantages. It’s heavier and more fragile compared to other materials, making it more expensive to transport and more prone to breakage. Additionally, the production of glass packaging requires a significant amount of energy and resources.

Despite these drawbacks, the durability and aesthetic appeal of glass packaging make it a popular choice in the beverage industry.

PET (Polyethylene Terephthalate) Bottles

We prefer PET bottles for superior beverage packaging due to their versatility and convenience. PET bottles offer numerous sustainability benefits, making them an excellent choice for environmentally-conscious consumers.

Here are four reasons why PET bottles are an ideal option for beverage packaging:

- Lightweight: PET bottles are lightweight, reducing transportation costs and energy consumption during distribution.

- Recyclability: PET is a highly recyclable material, enabling the creation of new bottles and reducing waste.

- Durability: PET bottles are durable, ensuring the safety and integrity of beverages throughout the manufacturing process and during transportation.

- Clarity: PET bottles have excellent clarity, allowing consumers to easily see the product inside, enhancing visibility and brand appeal.

The manufacturing process of PET bottles involves the use of polymerization, where ethylene glycol and terephthalic acid are combined to create PET resin. This resin is then molded into bottles using injection or blow molding techniques.

Tetra Pak Cartons

Moving on to Tetra Pak cartons, another excellent option for superior beverage packaging is available.

Tetra Pak cartons are made from multiple layers of paperboard, aluminum, and plastic, providing excellent protection and preserving the quality of beverages.

These cartons have gained significant market demand due to their sustainability benefits. The materials used in Tetra Pak cartons are recyclable, reducing the environmental impact compared to other packaging options.

Additionally, the lightweight nature of these cartons reduces transportation costs and energy consumption. Consumers appreciate the convenience of Tetra Pak cartons, as they’re easy to handle and store.

With the increasing focus on sustainable packaging solutions, the demand for Tetra Pak cartons is expected to grow.

Now, let’s move on to the next section, where we’ll explore the benefits of aluminum cans.

Aluminum Cans

Continuing our exploration of superior beverage packaging materials, let’s now delve into the advantages of aluminum cans. Aluminum cans offer several benefits over other packaging options, making them a popular choice in the industry.

Here are four reasons why aluminum cans are preferred:

- Lightweight and portable: Aluminum cans are lightweight, making them easy to carry and transport. This feature is especially beneficial for consumers on the go.

- Excellent barrier properties: Aluminum cans provide an excellent barrier against light, oxygen, and moisture, preserving the quality and taste of the beverage inside.

- Recyclable: Aluminum cans are highly recyclable, with a recycling rate of over 70%. This helps reduce the environmental impact and promotes a sustainable packaging solution.

- Alternative to glass bottles: Aluminum cans are an excellent alternative to glass bottles. They’re shatterproof, reducing the risk of breakage during transportation and handling.

Considering the environmental impact of aluminum cans and their many advantages, they’re a superior choice for beverage packaging.

Biodegradable and Compostable Materials

As we delve into the advantages of biodegradable and compostable materials for beverage packaging, it is important to consider their environmental benefits in comparison to aluminum cans. These sustainable alternatives offer a reduced environmental impact, making them an attractive option for those who desire to serve others while minimizing harm to the planet.

To better understand the environmental benefits of biodegradable and compostable materials, let’s compare them to aluminum cans.

| Environmental Impact | Biodegradable and Compostable Materials | Aluminum Cans |

|---|---|---|

| Resource Consumption | Use renewable resources | Require mining |

| Landfill Waste | Biodegrade and return to nature | Remain for centuries |

| Carbon Footprint | Produce less greenhouse gas emissions | Require energy-intensive production |

Frequently Asked Questions

Are Glass Packaging Materials More Expensive Than Other Types of Beverage Packaging Materials?

Glass packaging materials are generally more expensive than other types of beverage packaging materials. However, when considering the environmental impact, glass is often preferred due to its recyclability and ability to preserve the taste and quality of the beverage.

Can PET Bottles Be Recycled?

Yes, PET bottles can be recycled. In fact, they have a recycling viability of over 90%. This is important as it reduces their environmental impact and allows for the production of new bottles.

How Long Do Tetra Pak Cartons Typically Take to Decompose in a Landfill?

Tetra Pak cartons typically take a considerable amount of time to decompose in a landfill, which has a significant environmental impact. The decomposition rate of these cartons is an important factor to consider when evaluating their sustainability.

Are Aluminum Cans More Durable Than Other Types of Beverage Packaging Materials?

Aluminum cans, known for their resilience, outshine other beverage packaging materials in terms of durability. However, we must also consider the environmental impact. Plastic bottles, while less durable, have a significant detrimental effect on the environment.

What Are the Main Benefits of Using Biodegradable and Compostable Materials for Beverage Packaging?

Using biodegradable and compostable materials for beverage packaging offers numerous benefits. These eco-friendly materials provide sustainable packaging solutions, reducing environmental impact and waste. They are a responsible choice for those who value serving others and protecting the planet. In addition to minimizing pollution, biodegradable and compostable packaging helps conserve natural resources by promoting the use of renewable materials. For businesses and consumers alike, following green packaging tips for beverages, such as opting for plant-based or paper alternatives, can significantly reduce carbon footprints. By making conscious choices, we can collectively contribute to a healthier planet while still enjoying our favorite drinks.

Conclusion

In conclusion, when it comes to superior beverage packaging, the options are abundant.

Glass packaging offers a classic and elegant appeal, while PET bottles provide durability and convenience.

Tetra Pak cartons offer a sustainable and lightweight solution, and aluminum cans ensure freshness and portability.

Lastly, the use of biodegradable and compostable materials is gaining popularity, contributing to a greener and more environmentally friendly packaging industry.

With these exceptional options at our disposal, beverage packaging has reached new heights of innovation and practicality, making every sip a truly remarkable experience.

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.

Juice Manufacturing Process

Top 11 Trends Revolutionizing Juice Storage and Packaging

We provide the most up-to-date details on the top 11 trends changing the way juice is stored and packaged.

From sustainable packaging solutions to customizable juice pouches, these innovations are changing the game.

With advanced aseptic technology and convenient single-serve options, we’re keeping your juice fresher for longer.

Plus, we’re embracing eco-friendly materials and improved dispensing systems for a more sustainable future.

Join us as we explore the exciting world of juice storage and packaging, serving up the best options for you.

Key Takeaways

- Sustainable packaging solutions: Reusable containers and minimal waste solutions are being used to reduce excess packaging materials. Lightweight materials and optimized designs are being employed to minimize waste. Eco-friendly materials like plant-based bottles and compostable pouches are being used to contribute to a greener future.

- Innovative bottle designs: There is a move away from traditional cylindrical bottles towards embracing unique shapes and structures. Functional features like measuring caps and detachable mixing chambers are being integrated into bottle designs. Resealable spouts or caps are being used to prevent spills and maintain freshness. The focus is on sustainability with eco-friendly materials and refillable options.

- Advanced aseptic technology: Aseptic packaging techniques are being used to extend the shelf life and preserve the nutritional value of juices. This reduces reliance on preservatives and improves product safety and quality. Airtight packaging is used to prevent contamination and preserve taste and nutrients, leading to a reduction in food waste and cost-effectiveness.

- Technological advancements in aseptic packaging: High-temperature processing techniques are being used to kill harmful bacteria while preserving nutrients and flavors. Smart packaging solutions with airtight seals, UV-blocking materials, and temperature sensors are being developed. These advancements improve the quality and safety of packaged juices, resulting in longer shelf life and maintained freshness for a better consumer experience. Customizable options for juice packaging include personalized design options, custom labels, unique bottle shapes, and flavor customization for unique blends. Vibrant and eye-catching pouches are used for visual appeal, providing a tailored and personalized experience for consumers.

Sustainable Packaging Solutions

As consumers, we’re increasingly seeking sustainable packaging solutions for juice storage that align with our values and help reduce environmental impact. This shift in demand has encouraged companies to explore innovative, eco-friendly materials such as biodegradable plastics, recyclable glass, or cartons made from renewable resources. By prioritizing sustainable juice packaging options, both producers and consumers can play a key role in minimizing waste and reducing the dependence on single-use plastics. As a result, these efforts contribute to a more circular economy, where packaging materials are responsibly sourced and reused.

Reusable containers and minimal waste solutions have become popular choices in our quest for more eco-friendly options. Reusable containers offer a practical and sustainable alternative to single-use packaging, allowing us to reduce waste and minimize our carbon footprint. These containers are designed to be durable and long-lasting, ensuring that they can be used repeatedly without compromising the quality of the juice.

Additionally, minimal waste solutions focus on reducing excess packaging materials, such as using lightweight materials or optimizing packaging designs to minimize waste during production and transportation. By adopting these sustainable packaging solutions, we can contribute to a greener future and make a positive impact on the environment.

Now, let’s explore the next section, which discusses innovative bottle designs that are revolutionizing juice storage and packaging.

Innovative Bottle Designs

To continue our exploration of juice storage and packaging trends, let’s delve into the realm of innovative bottle designs that are transforming the way we store and package juices.

Juice bottle trends have shifted towards creative packaging solutions that not only enhance the visual appeal but also improve functionality and sustainability.

One of the latest trends in juice bottle designs is the use of unique shapes and structures. Brands are moving away from traditional cylindrical bottles and embracing unconventional forms such as square, triangular, or even asymmetrical designs. These eye-catching shapes not only stand out on the shelves but also offer ergonomic advantages, making it easier to grip and pour the juice.

Another innovative approach is the integration of functional features into the bottle design. For instance, some bottles now come with built-in measuring caps or detachable mixing chambers, allowing consumers to customize their juice experience. Additionally, brands are incorporating resealable spouts or caps that prevent spills and maintain freshness.

Sustainability is also a key focus in juice bottle designs. Many brands are opting for eco-friendly materials like recycled plastics or biodegradable alternatives. Additionally, some bottles feature minimalist designs, using less material and reducing waste. Some brands even offer refillable options, allowing consumers to reduce their environmental footprint by reusing the bottle.

Advanced Aseptic Technology

When it comes to juice storage and packaging, advanced aseptic technology is revolutionizing the industry.

Aseptic packaging offers numerous benefits, including extended shelf life, preservation of nutritional value, and reduced reliance on preservatives.

Technological advancements in aseptic processing have made it even more efficient and effective, ensuring the safety and quality of juices while minimizing the risk of contamination.

Aseptic Packaging Benefits

Implementing advanced aseptic technology offers numerous benefits for juice storage and packaging. By employing strict safety measures and contamination prevention techniques, aseptic packaging ensures that juice products remain fresh, safe, and of high quality for an extended period of time. This technology involves sterilizing the packaging materials and the juice separately, then sealing them in a sterile environment. The airtight packaging prevents the entry of microorganisms, oxygen, and light, which helps to preserve the taste, color, and nutritional value of the juice. Additionally, aseptic packaging eliminates the need for preservatives, as the sterilization process itself ensures product safety. This not only enhances the overall consumer experience but also reduces food waste and extends the shelf life of the juice, making it a cost-effective and sustainable solution.

| Aseptic Packaging Benefits |

|---|

| Enhanced product safety |

| Prolonged shelf life |

| Improved product quality |

| Reduction in food waste |

| Cost-effective and sustainable packaging |

Technological Advancements in Aseptic

With advancements in aseptic technology, we’ve seen remarkable improvements in juice storage and packaging.

Advanced processing techniques have revolutionized the way juice is treated and preserved, ensuring longer shelf life and maintaining the freshness of the product. These techniques involve subjecting the juice to high temperatures for a short time, killing harmful bacteria while preserving essential nutrients and flavors.

Additionally, smart packaging solutions have been developed to enhance the aseptic process. These innovative packages are designed to provide an airtight seal, preventing any contamination from entering the product. They also incorporate features such as UV-blocking materials to protect the juice from light exposure and temperature sensors to monitor and maintain optimal storage conditions.

These technological advancements in aseptic technology have greatly improved the quality and safety of packaged juices, offering consumers a longer-lasting and more enjoyable product.

Customizable Juice Pouches

Customizable juice pouches are an exciting trend in the beverage industry. They offer consumers the opportunity to personalize their juice packaging with custom design options. This allows brands to create unique and eye-catching packaging that stands out on the shelves.

With customizable juice pouches, consumers can have a more personal and interactive experience with their favorite juice brands.

Personalized Juice Packaging

Our research shows that a significant number of consumers are demanding more options when it comes to their juice packaging, and we’ve found that personalized juice pouches are meeting those demands effectively.

Personalized juice packaging allows consumers to have a unique and customized experience when enjoying their favorite beverages. One way this is achieved is through personalized labels. Consumers can now have their names or custom messages printed on the juice pouches, adding a personal touch to their drink.

Another aspect of personalized juice packaging is flavor customization. Consumers can choose from a variety of flavors and mix them together to create their own unique blend. This level of customization enhances the overall experience and gives consumers a sense of ownership over their juice choices.

With personalized juice packaging, consumers can now enjoy a truly tailored and personalized juice experience.

Custom Design Options

How can we enhance the customization of juice packaging to meet the growing demands of consumers?

One way is by offering custom label options and unique bottle shapes. Custom label options allow consumers to personalize their juice packaging with their own designs, logos, or messages. This not only adds a personal touch but also helps to create brand loyalty as customers feel a connection to the product. Additionally, unique bottle shapes can make the juice stand out on the shelves and catch the attention of potential buyers. Whether it’s a sleek and modern shape or a playful and whimsical design, the possibilities are endless.

By providing these custom design options, juice manufacturers can cater to the individual preferences of their customers and create a memorable and enjoyable experience.

As we move forward, let’s explore another important trend in juice storage and packaging: biodegradable and compostable materials.

Biodegradable and Compostable Materials

We are witnessing a growing adoption of biodegradable and compostable materials in the juice storage and packaging industry. This trend is driven by the increasing demand for sustainable materials and the desire to reduce environmental impact.

Biodegradable packaging offers a solution to the problem of plastic waste, as it breaks down naturally into harmless substances over time. These materials are made from renewable resources such as plant-based plastics, paper, or wood pulp, making them a more sustainable alternative to traditional packaging materials.

Compostable materials, on the other hand, can be broken down in composting facilities, turning into nutrient-rich soil.

Smart Packaging With Interactive Features

When it comes to juice packaging, one of the trends revolutionizing the industry is the integration of smart features that enhance the user experience.

With innovative packaging designs, juice brands are able to offer interactive elements that engage consumers in new and exciting ways. These interactive features can include QR codes that provide information about the juice’s origin and nutritional content, augmented reality experiences that bring the packaging to life, or even sensors that monitor the freshness of the juice.

Enhanced User Experience

One of the key trends revolutionizing juice storage and packaging is the incorporation of interactive features in smart packaging to enhance the user experience. This innovation aims to provide improved functionality and user-friendly designs that cater to the needs and preferences of consumers.

Smart packaging with interactive features allows users to have a more engaging and convenient experience when using juice products. For example, some juice packaging now includes QR codes that can be scanned with a smartphone to provide detailed product information, recipes, or even personalized recommendations based on the user’s preferences.

Additionally, some smart packaging designs come with built-in sensors that can detect the freshness of the juice and provide real-time updates to the user. These interactive features not only make the juice storage and packaging experience more enjoyable but also provide valuable information to the consumers, ensuring they make informed choices.

Innovative Packaging Designs

As technology continues to advance, juice storage and packaging are being revolutionized by innovative designs that incorporate smart packaging with interactive features. These sustainable bottle designs not only reduce waste but also provide a unique and engaging experience for consumers.

Here are some of the latest trends in innovative packaging designs:

- Interactive Labels: Labels that change color or provide additional information when touched or scanned, enhancing the user experience and promoting brand engagement.

- Smart Caps: Caps that can monitor freshness, track consumption, or even provide personalized recommendations based on the user’s preferences.

- Augmented Reality Packaging: Packaging that comes to life through augmented reality, allowing consumers to interact with virtual elements and experience the product in a whole new way.

- Smart Juice Dispensing: Bottles with built-in sensors and dispensing mechanisms that measure and dispense the perfect amount of juice, reducing waste and ensuring consistent quality.

These innovative packaging designs not only make juice storage more sustainable but also enhance the overall consumer experience.

Now let’s explore the next trend in juice storage and packaging: extended shelf life techniques.

Extended Shelf Life Techniques

To achieve longer shelf life for juices, we employ various techniques. One of these techniques is pasteurization. Pasteurization involves heating the juice to a specific temperature to kill harmful bacteria and extend its shelf life. This process ensures that the juice remains safe for consumption for an extended period.

Another technique we use is aseptic packaging. Aseptic packaging involves packaging the juice in sterilized containers under sterile conditions to prevent any contamination. This packaging technique helps to maintain the freshness and quality of the juice, allowing it to be stored for longer periods without the need for refrigeration.

These extended shelf life techniques not only ensure the safety and quality of the juice but also contribute to reducing food waste and promoting sustainable packaging solutions.

As we move forward, let’s now explore the next section on convenient single-serve options.

Convenient Single-Serve Options

Moving on to the next trend in juice storage and packaging, we’ll now explore the convenient single-serve options available. In today’s fast-paced world, consumers are constantly seeking convenient grab and go solutions for their daily needs, and the juice industry is no exception. Portable juice options have become increasingly popular, allowing individuals to enjoy their favorite beverages on the move.

When it comes to single-serve options, sustainability is also a key consideration. Consumers are now demanding sustainable single-serve alternatives that minimize waste and environmental impact. To meet this demand, juice manufacturers are turning to innovative packaging materials and designs that are recyclable or made from renewable resources. Some popular sustainable single-serve alternatives include paper-based cartons, biodegradable bottles, and compostable pouches. These options not only provide convenience but also align with the growing eco-consciousness of consumers.

Transitioning into the subsequent section about enhanced juice freshness preservation, it’s important to note that while convenience is a top priority, consumers also want their juice to be fresh and flavorful.

Enhanced Juice Freshness Preservation

Exploring methods for enhancing juice freshness preservation, we’ve discovered innovative techniques that revolutionize juice storage and packaging.

One of these techniques is juice freshness monitoring, which allows producers to track the freshness of their products throughout the supply chain. By using sensors to measure factors like temperature and oxygen levels, producers can ensure that their juice remains fresh and of high quality.

Another method that has gained popularity is the use of vacuum-sealed containers. By removing the air from the packaging, vacuum-sealed containers help to preserve the freshness of the juice for a longer period of time. This technique prevents oxidation and microbial growth, ensuring that the juice maintains its flavor and nutritional value.

With these advancements in juice freshness preservation, consumers can enjoy a longer shelf life and a better tasting product.

Eco-Friendly Juice Storage Solutions

Our commitment to sustainability is reflected in our use of eco-friendly juice storage solutions. We understand the importance of reducing our environmental impact while still providing high-quality products to our customers.

Here are some sustainable storage options we utilize:

- Biodegradable Packaging: We use packaging materials that are made from renewable resources and can break down naturally, reducing waste in landfills.

- Recyclable Bottles: Our juice bottles are made from recyclable materials, allowing them to be reused or repurposed after use.

- Efficient Warehousing: We optimize our warehousing practices to minimize energy consumption and maximize space utilization, reducing our carbon footprint.

- Plant-Based Refrigeration: We utilize refrigeration systems that use natural refrigerants and energy-efficient technologies, ensuring minimal environmental impact.

Improved Juice Dispensing Systems

To further enhance our commitment to sustainability, we’ve implemented improved juice dispensing systems that offer greater efficiency and convenience.

These improved dispensing mechanisms are designed to minimize waste and ensure that every drop of juice is efficiently dispensed.

We’ve incorporated automated juice dispensers that use advanced technology to accurately measure and dispense the desired amount of juice with precision.

These automated systems eliminate the need for manual pouring, reducing the risk of spills and contamination.

Additionally, the automated dispensers are equipped with intuitive touchscreens, making it easier for users to select their desired juice and customize their servings.

With these improved juice dispensing systems, we’re able to provide our customers with a seamless and enjoyable experience while reducing our environmental impact.

Frequently Asked Questions

How Much Does Sustainable Packaging Solutions for Juice Storage Cost?

Sustainable packaging solutions for juice storage vary in cost depending on factors such as materials used, size of packaging, and quantity ordered. A cost analysis is essential to determine the most cost-effective option for your business.

Are There Any Regulations or Certifications for Biodegradable and Compostable Juice Packaging Materials?

There are various regulations and certifications for biodegradable and compostable juice packaging materials. These ensure that the materials meet specific standards for environmental impact. It’s important to consider these when choosing sustainable packaging solutions.

Can Customizable Juice Pouches Be Easily Recycled?

Customizable juice pouches can be easily recycled, reducing their environmental impact. We’ve found that recycling feasibility largely depends on the type of material used, so it’s important to choose packaging that aligns with sustainability goals.

How Do Advanced Aseptic Technology Techniques Affect the Taste and Nutritional Value of the Juice?

Advanced aseptic technology techniques act as a guardian, preserving both the taste and nutritional value of juice. By maintaining a sterile environment, these techniques ensure that the juice remains fresh and free from harmful microorganisms.

Are There Any Health Concerns Associated With Smart Packaging With Interactive Features?

Smart packaging benefits consumers by providing interactive features that enhance convenience and engagement. While there may be concerns about the health implications, thorough research and testing can ensure that these features do not compromise the safety or nutritional value of the juice.

Conclusion

In conclusion, the juice storage and packaging industry is experiencing a revolution that’s transforming the way we enjoy our favorite beverages. With sustainable packaging solutions, innovative bottle designs, and advanced aseptic technology, juice lovers can now savor their drinks with peace of mind.

The customizable juice pouches, biodegradable materials, and convenient single-serve options offer convenience without compromising the environment. The improved freshness preservation and eco-friendly storage solutions guarantee that every sip is bursting with flavor.

Say goodbye to ordinary juice packaging and embrace the exciting future of juice storage and packaging.

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.

-

Popular Juice Brands4 weeks ago

Popular Juice Brands4 weeks ago10 Top-Rated Organic Juice Brands to Try

-

Popular Juice Brands4 weeks ago

Popular Juice Brands4 weeks ago9 Best No-Sugar-Added Popular Juice Brands

-

Health Benefits of Juice2 weeks ago

Health Benefits of Juice2 weeks agoHow Much Bottled Lemon Juice Equals 1 Lemon

-

Vegetable Juices4 weeks ago

Vegetable Juices4 weeks ago12 Top Organic Vegetable Juice Brands Reviewed

-

Juice Tips and Tricks1 week ago

Juice Tips and Tricks1 week agoHow Long Does Lemon Juice Last After Expiration Date

-

Juice Tips and Tricks2 weeks ago

Juice Tips and Tricks2 weeks agoHow Long Does Juice Last After Juicing

-

Juice Tips and Tricks2 weeks ago

Juice Tips and Tricks2 weeks ago2 Lemons Equal How Much Juice

-

Vetted3 months ago

Vetted3 months ago15 Best Juices for Diabetics: Refreshing Options That Won’t Spike Your Blood Sugar