Juice Manufacturing Process

How to Optimize Juice Production on a Budget

Calling all budget-conscious juice makers! We have the insider advice and strategies essential for enhancing your juice production.

From sourcing affordable fruit and ingredients to streamlining the extraction process and minimizing waste, we’ve got you covered.

With our practical knowledge and cost-saving strategies, you’ll be able to maximize your yield and serve your customers with delicious, budget-friendly juice.

Get ready to take your juice production to the next level without breaking the bank!

Key Takeaways

- Establish relationships with local farmers and growers

- Buy in bulk from wholesale suppliers

- Invest in high-quality juicers

- Implement efficient extraction techniques

Sourcing Affordable Fruit and Ingredients

To source affordable fruit and ingredients, we explore various options that fit within our budget constraints.

One option is to establish relationships with local farmers and growers. By purchasing directly from them, we can often negotiate lower prices and ensure the freshness of our produce.

Another option is to buy in bulk from wholesale suppliers. Buying in large quantities allows us to take advantage of discounted prices.

Additionally, we can consider using frozen fruits and vegetables, which are often more cost-effective than fresh produce. These frozen options still retain much of their nutritional value and can be a great alternative when fresh ingredients aren’t readily available.

Lastly, we can explore partnerships with food banks or community organizations that receive surplus or donated produce. This not only helps us source affordable ingredients but also allows us to contribute to the community by reducing food waste.

Streamlining the Juice Extraction Process

After sourcing affordable fruit and ingredients, we frequently streamline the juice extraction process to maximize efficiency and minimize costs. Here are three ways we optimize our juice production:

- Invest in high-quality juicers: Our juicers are designed for commercial use, allowing us to extract juice quickly and efficiently without compromising on quality. These machines are durable and easy to clean, ensuring a smooth and uninterrupted production process.

- Implement standardized juicing procedures: By establishing clear guidelines and protocols for juicing, we eliminate guesswork and improve consistency. This helps us save time and reduce errors, resulting in a more efficient operation.

- Optimize ingredient preparation: We carefully wash and prepare the fruits before juicing, removing any blemishes or spoiled parts. This not only ensures the quality of the juice but also prevents clogging and damage to the juicers.

By streamlining the juice extraction process, we can maximize our productivity and minimize waste.

Now, let’s explore how we further maximize yield and minimize waste in our juice production.

Maximizing Yield and Minimizing Waste

To maximize our yield and minimize waste, we consistently monitor and adjust our production processes.

By carefully tracking our raw material usage and implementing efficient extraction techniques, we ensure that every drop of juice is extracted from the fruits.

We also prioritize proper handling and storage of the fruits to avoid spoilage and waste.

Additionally, we regularly assess our equipment and make necessary adjustments to optimize efficiency and minimize losses during juice production.

This proactive approach allows us to maximize our output and reduce waste, ultimately helping us serve our customers better.

As we move forward, we’ll now focus on implementing efficient packaging and labeling strategies to further enhance our juice production process.

Implementing Efficient Packaging and Labeling Strategies

First, we’ll explore three cost-effective strategies for implementing efficient packaging and labeling in our juice production process.

- Standardize packaging sizes: By using uniform packaging sizes for our juice products, we can optimize production efficiency and reduce costs associated with different packaging options. This will also streamline the labeling process, making it easier to create and apply labels consistently.

- Invest in automated labeling equipment: Manual labeling can be time-consuming and prone to errors. By investing in automated labeling equipment, we can increase efficiency and accuracy in our packaging process. This will ensure that every juice bottle is properly labeled, reducing the risk of mislabeling or incorrect information.

- Optimize label design: A well-designed label not only enhances the visual appeal of our juice products but also provides essential information to our customers. By optimizing label design, we can create a cohesive and attractive brand image while ensuring that all required labeling elements are included.

Leveraging Technology for Cost Savings

We can leverage technology to achieve cost savings in our juice production process. By implementing the right technological solutions, we can streamline operations, reduce waste, and improve overall efficiency. Here are some ways technology can help us save costs:

| Technology Solution | Cost Savings Benefits |

|---|---|

| Automated juicing machines | Increase juice extraction efficiency and reduce labor costs |

| Smart inventory management systems | Minimize waste by accurately tracking ingredient usage |

| Energy-efficient equipment | Lower utility bills by reducing energy consumption |

| Cloud-based data analytics | Optimize production schedules and minimize downtime |

| Online marketplace platforms | Source ingredients and packaging materials at competitive prices |

Frequently Asked Questions

How Do I Calculate the Cost per Bottle of Juice Produced?

To calculate the cost per bottle of juice produced, we need to consider the total production costs, including ingredients, labor, and packaging. Divide the total cost by the number of bottles produced to find the cost per bottle.

What Are Some Strategies for Finding Affordable Fruit Suppliers?

To find affordable fruit suppliers, we ask local farmers about surplus crops, compare prices at farmers markets, and negotiate bulk discounts. It’s all about building relationships and being resourceful to keep our juice production costs low.

Are There Any Tips for Reducing Energy Consumption During the Juice Extraction Process?

There are tips for reducing energy consumption during the juice extraction process. We can explore efficient equipment options, optimize production schedules, and implement energy-saving practices to minimize costs and environmental impact.

How Can I Ensure the Freshness and Quality of the Juice While Minimizing Waste?

To ensure the freshness and quality of juice while minimizing waste, we focus on efficient production processes, storage techniques, and regular quality checks. By doing so, we can serve you the best juice experience without compromising on taste or waste.

What Technological Advancements Can Be Utilized to Improve Juice Production Efficiency and Reduce Costs?

To improve juice production efficiency and reduce costs, we can utilize technological advancements. These advancements can streamline the production process, automate tasks, and optimize resource usage, ultimately increasing productivity and profitability.

Conclusion

In conclusion, optimizing juice production on a budget isn’t only achievable but also essential for small businesses.

By sourcing affordable fruit and ingredients, streamlining the extraction process, maximizing yield, and implementing efficient packaging strategies, businesses can save costs without compromising quality.

As the saying goes, ‘A penny saved is a penny earned,’ and with these practical strategies, juice producers can maximize their profits while delivering a refreshing and cost-effective product to their customers.

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.

Juice Manufacturing Process

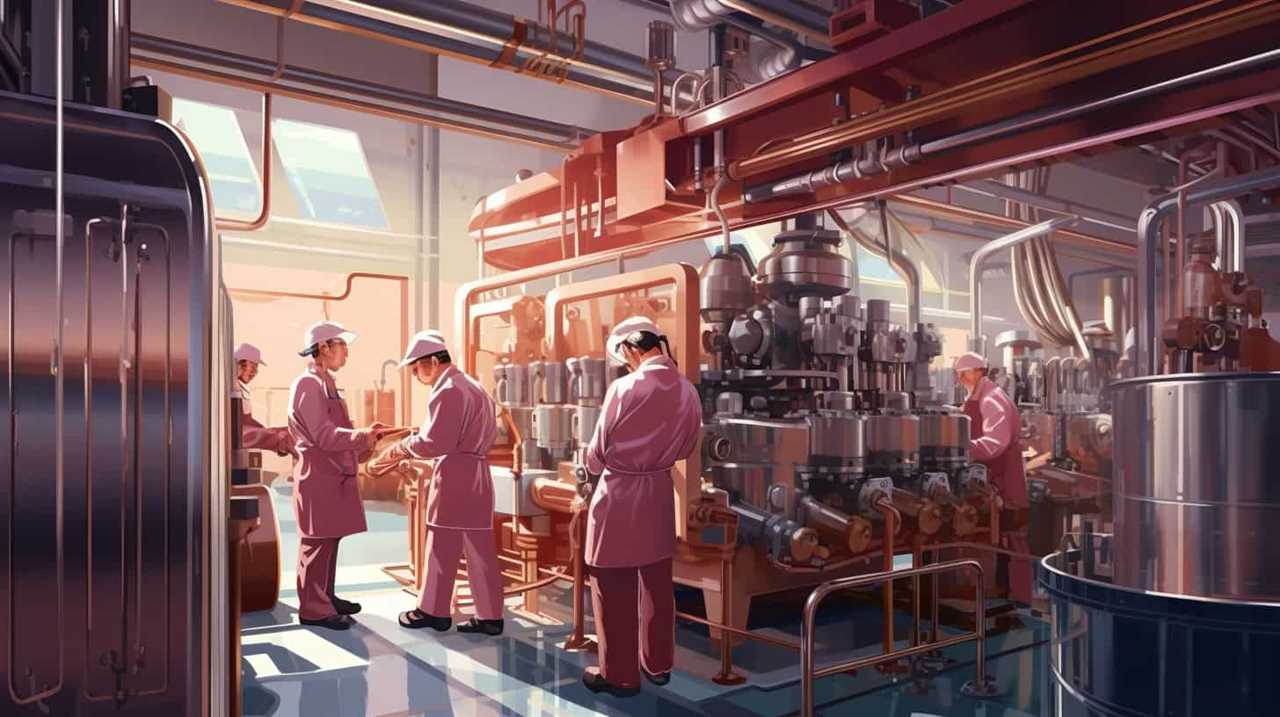

Ensuring Juice Quality: The Manufacturing Process

Knowing that quality is extremely important to you, we are excited to share some information on the process of juice production. Our production process starts with meticulously selecting top-notch fruits to guarantee freshness and flavor. Thanks to revolutionary advancements in juice manufacturing, we have improved both the efficiency and quality control of our processes, leading to consistently superior products. These innovations also aid in preserving more natural nutrients and flavors, providing an exceptional juice experience with every sip.

Did you know that over 60% of juice production starts with sourcing fresh fruits?

From the moment we extract the juice to the final steps of testing for quality and safety, we take every step seriously.

Our precise and scientific approach ensures that every bottle of juice we produce meets the highest standards.

Let us guide you through the journey of ensuring juice quality.

Key Takeaways

- Sourcing fresh fruits involves careful selection and quality control measures to ensure only the finest fruits are chosen.

- The mechanical process of extracting juice efficiently separates juice from pulp, ensuring high-quality juice.

- Pasteurization eliminates harmful bacteria without compromising the taste or nutritional content of the juice.

- Rigorous testing for physical, chemical, and microbiological properties ensures that the juice is safe and of the highest quality.

Sourcing Fresh Fruits

We source fresh fruits from local farms and suppliers to ensure the highest quality for our juice manufacturing process. Our commitment to serving our customers with the best juice starts with carefully selecting the freshest fruits available.

We work closely with local farmers and suppliers who share our passion for quality and sustainability. Through rigorous quality control measures, we ensure that only the finest fruits are chosen for our juice manufacturing. We carefully inspect each fruit for ripeness, color, and texture, guaranteeing that only the best make it into our juice.

Our scientific approach involves analyzing the nutritional content of each fruit and conducting taste tests to ensure optimal flavor profiles. By sourcing locally, we not only support our community but also minimize transportation time, preserving the freshness and nutritional value of the fruits.

Extracting Juice From the Fruits

To extract juice from the fruits, we employ a mechanical process that efficiently separates the liquid from the pulp. We begin by washing and sorting the fruits to ensure they’re clean and free from any contaminants.

Next, the fruits are fed into a machine called a juice extractor. This machine uses sharp blades to break down the fruits and release the juice.

The pulp and seeds are then separated from the juice using a centrifuge, which spins the mixture at high speeds. The centrifugal force causes the heavier pulp and seeds to settle at the bottom while the lighter juice is collected.

Pasteurization and Bottling

How do we ensure the quality of our juice during the pasteurization and bottling process? Here are some steps we take to guarantee the highest standards:

- Pasteurization: We heat the juice to a specific temperature to eliminate harmful bacteria, ensuring its safety without compromising taste or nutrition.

- Filtration: We meticulously filter the juice to remove any impurities, resulting in a clean and clear product.

- Quality control: Our experienced team conducts regular checks throughout the process to ensure everything meets our strict quality standards.

- Bottling: We use state-of-the-art bottling equipment to ensure a hygienic and efficient process, minimizing the risk of contamination.

- Sealing and labeling: Our automated systems carefully seal each bottle, preserving the freshness of the juice, and apply accurate labeling, providing clear information to our customers.

Testing for Quality and Safety

After completing the pasteurization and bottling process, we move on to testing the juice for quality and safety. This step is crucial in ensuring that the juice we produce is safe and of the highest quality for our consumers.

We conduct a series of tests to evaluate the juice’s physical, chemical, and microbiological properties. These tests include measuring pH levels, checking for the presence of contaminants such as pesticides and heavy metals, and assessing microbial counts. We also perform sensory evaluations to assess the juice’s taste, color, and aroma.

Packaging and Distribution

Once the testing process is completed, we package and distribute the juice to ensure its quality and safety. Our packaging and distribution process is meticulously designed to protect the integrity of the juice and deliver it to our customers in pristine condition. Here is a breakdown of the steps we take:

- We use high-quality, food-grade packaging materials that are specifically designed to preserve freshness and prevent contamination.

- The juice is carefully filled into the packaging, ensuring accurate measurements and avoiding any spills or leaks.

- Each package is sealed using advanced sealing technology to maintain a tight and secure closure.

- We employ rigorous quality control measures to ensure that every package meets our strict standards before it’s approved for distribution.

- Finally, the juice is transported in climate-controlled vehicles to maintain optimal temperature conditions throughout the distribution process.

Frequently Asked Questions

How Long Does It Take for the Fruits to Be Sourced and Delivered to the Manufacturing Facility?

It takes a varying amount of time for the fruits to be sourced and delivered to our manufacturing facility. Factors such as location, seasonality, and supplier availability can affect the duration of this process.

What Methods Are Used to Extract Juice From the Fruits?

We extract juice from the fruits using advanced methods. These methods ensure maximum extraction and retention of nutrients. Our goal is to provide high-quality juice that is both delicious and nutritious for our customers.

What Temperature and Duration Is Used During the Pasteurization Process?

During pasteurization, we heat the juice to a specific temperature and hold it for a certain duration. This process helps to eliminate harmful bacteria and ensure the safety and quality of the juice.

How Is the Quality and Safety of the Juice Tested?

We ensure juice quality by testing for safety and taste. Our team uses rigorous quality control measures and advanced laboratory techniques to analyze the juice for any contaminants or abnormalities.

How Are the Bottles Packaged and Transported for Distribution?

We carefully package and transport the juice bottles for distribution to ensure their quality and safety. Our process includes secure packaging to prevent breakage, temperature control to maintain freshness, and efficient logistics for timely delivery to our customers.

Conclusion

In conclusion, the manufacturing process of ensuring juice quality involves several key steps.

First, fresh fruits need to be sourced. This involves carefully selecting fruits that are ripe and free from defects.

Next, the juice needs to be extracted from the fruits. This can be done through various methods such as pressing or centrifugation.

After extraction, the juice needs to undergo pasteurization. This step involves heating the juice to a specific temperature to kill any harmful bacteria or pathogens.

Once pasteurized, the juice is then ready for bottling. This step involves filling the juice into clean and sanitized bottles, ensuring that they are sealed properly to maintain freshness.

Testing for quality and safety is another crucial step in the process. This involves conducting rigorous tests to ensure that the juice meets all safety and quality standards.

Finally, the juice is ready for packaging and distribution. It needs to be packaged in a way that is convenient and appealing to consumers. Once packaged, it can be distributed to retailers or directly to consumers.

Overall, maintaining high standards throughout each step of the manufacturing process is essential. By doing so, manufacturers can deliver a product that is not only safe but also of the highest quality. This ensures that consumers can enjoy refreshing and nutritious juice with confidence.

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.

Juice Manufacturing Process

Advancements Revolutionizing the Juice Manufacturing Process

Dear ladies and gentlemen, it brings me great joy to present to you a new era in juice production that is revolutionizing the way we make and enjoy our favorite beverages. Please join us as we explore the cutting-edge advancements that are reshaping the juicing industry.

With cold-pressed technology, high-pressure processing, automated extraction systems, sustainable packaging solutions, and the integration of artificial intelligence in quality control, we are witnessing a new era of innovation that serves the pursuit of excellence in delivering the finest juice experiences.

Key Takeaways

- Cold-pressed technology: This technology uses hydraulic pressure instead of heat or centrifugal force to retain more nutrients and enzymes in the juice, resulting in a healthier and fresher product.

- HPP (High Pressure Processing): HPP is a technique that subjects juice to extremely high pressure to destroy harmful bacteria and extend shelf life while retaining the natural taste, color, and nutritional value of the juice, reducing the need for additives and increasing safety.

- Automated extraction systems: These systems minimize human intervention and utilize sensors and robotics for precision and efficiency, resulting in consistent quality and maximum juice yield while cutting waste.

- Sustainable practices: Implementing sustainable packaging, such as easily recyclable materials and exploring biodegradable options, streamlining design to reduce waste, and promoting a circular economy, are crucial in minimizing the environmental impact of juice manufacturing.

Cold-Pressed Technology

Cold-pressed technology has transformed the juice manufacturing process, allowing us to produce high-quality, nutrient-rich juices that retain their natural flavors and benefits.

This revolutionary method involves extracting juice from fruits and vegetables using hydraulic pressure, rather than heat or centrifugal force. By avoiding heat, cold-pressed technology retains more of the vital nutrients and enzymes present in the produce, resulting in juices that aren’t only packed with flavor but also highly beneficial for our health.

The process begins with carefully selected organic fruits and vegetables, which are then washed, chopped, and pressed to extract the juice. The juice is then immediately bottled, ensuring that it remains fresh and vibrant.

With cold-pressed technology, we’re able to provide our customers with juices that aren’t only delicious but also nourishing, helping them to lead healthier lives.

High-Pressure Processing (HPP)

One innovation that further enhances the juice manufacturing process is High-Pressure Processing (HPP), a technique that builds upon the benefits of cold-pressed technology. HPP involves subjecting bottled juice to extremely high pressure, typically between 87,000 and 100,000 pounds per square inch (psi), for a short duration of time.

This process effectively destroys harmful bacteria and extends the shelf life of the juice, without the need for preservatives or heat. HPP also helps to retain the natural taste, color, and nutritional value of the juice, ensuring a high-quality product for consumers.

Additionally, HPP reduces the need for additives and increases the safety of the juice, making it a valuable tool for juice manufacturers who prioritize delivering safe, healthy, and flavorful products to their customers.

Automated Extraction Systems

To further improve the juice manufacturing process, we’ve implemented automated extraction systems that streamline the production and enhance efficiency. These systems are designed to extract juice from fruits and vegetables with minimal human intervention, ensuring consistent quality and maximizing output.

By automating the extraction process, we eliminate the need for manual labor, reducing the risk of human error and increasing productivity. These systems utilize advanced technologies such as sensors and robotics to monitor and control the entire extraction process, from fruit sorting to juice extraction. They’re equipped with precision cutting mechanisms that efficiently extract the juice while minimizing waste.

Additionally, automated extraction systems can be programmed to adjust extraction parameters based on the specific fruits or vegetables being processed, resulting in optimal juice yield and quality.

Sustainable Packaging Solutions

Implementing sustainable packaging solutions is crucial for revolutionizing the juice manufacturing process. Here are three key aspects to consider:

- Recyclable Materials: Opting for packaging materials that are easily recyclable, such as cardboard or glass, reduces waste and promotes a circular economy. By using materials that can be recycled and reused, we can minimize the environmental impact of juice production.

- Biodegradable Alternatives: Exploring biodegradable packaging options, like plant-based plastics, can help mitigate the long-term effects of plastic waste. These materials break down naturally, reducing pollution and minimizing harm to the ecosystem.

- Minimalist Design: Streamlining packaging design to use fewer materials not only reduces costs but also decreases the carbon footprint. By eliminating unnecessary layers or components, we can create more sustainable packaging solutions that still protect the product while minimizing waste.

Transitioning into the next section, artificial intelligence in quality control, allows us to explore how technology can further enhance sustainability efforts in the juice manufacturing process.

Artificial Intelligence in Quality Control

We utilize artificial intelligence for quality control in our juice manufacturing process. By incorporating AI technology into our production line, we’re able to ensure that every bottle of juice meets the highest standards of quality and safety.

AI algorithms analyze various parameters such as color, consistency, and taste to identify any deviations from the desired specifications. This automated system allows us to detect and reject any defective products, minimizing the risk of subpar juice reaching the market.

Additionally, AI-powered sensors continuously monitor the production environment, alerting us to any anomalies or potential issues that may affect the quality of the juice.

Frequently Asked Questions

How Long Does the Cold-Pressed Technology Process Typically Take for Juice Manufacturing?

Typically, the cold-pressed technology process for juice manufacturing takes approximately 5-10 minutes. This innovative method ensures maximum retention of nutrients and flavors, resulting in a high-quality and flavorful juice for our customers.

What Are the Advantages of Using High-Pressure Processing (Hpp) in Juice Production?

High-pressure processing (HPP) in juice production offers several advantages. It helps retain the nutritional value, taste, and freshness of the juice while ensuring safety by eliminating harmful bacteria.

How Do Automated Extraction Systems Improve Efficiency in Juice Manufacturing?

Automated extraction systems improve efficiency in juice manufacturing by streamlining the process, reducing manual labor, and increasing production speed. These advancements allow us to serve customers faster and meet the growing demand for quality juice products.

What Are the Sustainable Packaging Solutions Commonly Used in the Juice Industry?

Sustainable packaging solutions commonly used in the juice industry include biodegradable bottles, compostable pouches, and recyclable cartons. These advancements reduce environmental impact and align with our commitment to serving others while protecting the planet.

How Does Artificial Intelligence Contribute to Quality Control in Juice Manufacturing?

Artificial intelligence contributes to quality control in juice manufacturing by utilizing advanced algorithms and machine learning. It allows for real-time monitoring, detecting defects, and ensuring consistency in taste, texture, and color.

Conclusion

In conclusion, these groundbreaking advancements in the juice manufacturing process have completely transformed the industry.

With cold-pressed technology, high-pressure processing, automated extraction systems, sustainable packaging solutions, and even artificial intelligence in quality control, the future of juice production is looking incredibly efficient and innovative. These advancements streamline the industrial juice manufacturing steps, ensuring minimal waste and maximum yield from raw ingredients. Automation and AI not only improve the consistency and safety of the final product but also help companies meet growing consumer demands for transparency and sustainability. As technology continues to evolve, juice producers are poised to offer beverages that are fresher, safer, and more environmentally responsible than ever before.

So, say goodbye to mediocre juice and say hello to a revolution in your glass!

It’s time to embrace the juice evolution and taste the fruits of progress. Cheers to a juicier future!

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.

Juice Manufacturing Process

14 Detailed Steps in Industrial Juice Manufacturing

Ladies and gentlemen, join us as we delve into the fascinating world of industrial juice production.

We’ll guide you through 14 meticulously detailed steps, unveiling the secrets behind crafting that perfect glass of refreshing goodness.

From sourcing and sorting the finest fruits, to extracting and filtering the juice, to ensuring safety through pasteurization and quality control tests, we leave no stone unturned.

So grab a seat and prepare to be amazed as we take you behind the scenes of this meticulous process.

Key Takeaways

- Select and procure raw fruits from trusted suppliers and growers based on reputation, quality standards, and sustainable farming practices.

- Thoroughly clean and sort fruits to ensure only the best ones are used for juice production.

- Utilize mechanical extractors, fine mesh sieves, enzymatic treatment, and centrifugal separators to extract juice from the fruits.

- Implement effective purification techniques such as filtration, sedimentation, and activated carbon filtration to remove impurities from the juice.

Harvesting and Sourcing Raw Fruits

In our industrial juice manufacturing process, we begin by carefully selecting and procuring raw fruits from various trusted suppliers and growers. We understand the importance of sourcing high-quality fruits to ensure the best taste and nutritional value in our juices.

Our team meticulously evaluates the suppliers and growers based on their reputation, quality standards, and adherence to sustainable farming practices. We prioritize partnerships with local farmers who share our commitment to serving others and promoting a healthier lifestyle.

Once the fruits are harvested, they’re quickly transported to our facility to maintain freshness and prevent any loss of flavor or nutrients. By following this precise and methodical approach in sourcing our raw materials, we guarantee that our customers receive the finest, most nourishing juices available.

Sorting and Cleaning the Fruits

We carefully sort and clean the harvested fruits to ensure the highest quality in our industrial juice manufacturing process.

First, we sort the fruits based on their size, color, and ripeness. This ensures that only the best fruits are used for our juice production.

Next, we thoroughly clean the fruits to remove any dirt, debris, or pesticides. This is done using a combination of water, gentle scrubbing, and food-safe cleaning solutions.

Lastly, we inspect each fruit individually to identify and remove any damaged or spoiled ones.

Extracting Juice From the Fruits

To extract juice from the fruits, our team utilizes modern machinery and techniques.

First, we carefully wash and sanitize the fruits to remove any dirt or impurities.

Then, we employ mechanical extractors to separate the juice from the pulp. These extractors use high-speed rotating blades to break down the fruits and release the juice.

The resulting mixture is then passed through a fine mesh sieve to remove any remaining solids.

Next, we employ a process called enzymatic treatment, where natural enzymes are added to break down the remaining pulp and enhance the juice extraction.

Finally, the juice is clarified using centrifugal separators to remove any suspended particles and ensure a clear and visually appealing product.

Our efficient extraction methods allow us to produce large quantities of high-quality juice that meets the demands of our customers.

Filtering the Juice to Remove Impurities

To ensure the highest quality of juice, it’s essential to implement effective purification techniques. Removing impurities from the juice is a crucial step in the manufacturing process.

Various methods can be employed, such as filtration, sedimentation, and centrifugation, to eliminate unwanted particles and substances.

Purification Techniques for Juice

During the purification process, impurities in the juice are effectively removed through the use of various filtering techniques. These techniques are crucial in ensuring that the juice is clean, safe, and of high quality.

Here are three filtration methods commonly employed in industrial juice manufacturing:

- Mechanical filtration: This method involves passing the juice through screens or filters that physically trap and remove solid particles, such as pulp and seeds. It’s the initial step in the purification process and helps remove larger impurities.

- Microfiltration: This technique uses membranes with tiny pores to separate particles based on size. It effectively removes smaller impurities, including microorganisms and fine sediment, ensuring the juice is clear and free from contaminants.

- Activated carbon filtration: Activated carbon is used to absorb and remove organic compounds, such as chemicals and odors, from the juice. This process helps improve the taste, odor, and color of the final product.

Impurity Removal Methods

One important step in industrial juice manufacturing is the removal of impurities through various filtration methods. To ensure the highest quality juice, it’s crucial to eliminate any unwanted particles or substances that may affect taste, appearance, or safety.

Filtration can be achieved using different techniques, such as sedimentation, centrifugation, and membrane filtration. Sedimentation involves allowing the juice to settle, allowing heavier particles to sink to the bottom.

Centrifugation uses centrifugal force to separate impurities from the juice. Membrane filtration utilizes semipermeable membranes to physically remove impurities based on size. These filtration methods ensure a clean and pure juice ready for further processing.

Once the impurities have been removed, the next step is to pasteurize the juice to ensure its safety.

Pasteurizing the Juice to Ensure Safety

Now let’s turn our attention to the crucial step of pasteurizing the juice to ensure its safety. Pasteurization involves carefully controlling the temperature and duration of heat treatment to eliminate harmful microorganisms while preserving the flavor and nutritional content of the juice.

This step is of utmost importance in industrial juice manufacturing as it plays a vital role in preventing foodborne illnesses and extending the shelf life of the final product.

Temperature and Duration

We heat treat the juice to ensure its safety by pasteurizing it at specific temperatures and for predetermined durations. This process kills harmful bacteria and extends the shelf life of the juice.

To achieve the desired level of safety, we follow a precise methodical approach:

- We carefully monitor the temperature during pasteurization to ensure it reaches a minimum of 160°F (71°C). This temperature is necessary to destroy pathogens, such as E. coli and Salmonella, that may be present in the juice.

- We maintain this temperature for a predetermined duration. The duration varies depending on the type of juice, but it typically ranges from 15 to 30 seconds.

- After pasteurization, we rapidly cool the juice to prevent the growth of any surviving bacteria.

Importance of Pasteurization?

To ensure the safety of our juice products, it’s crucial to understand the importance of pasteurization in the manufacturing process.

Pasteurization is a heat treatment method used to eliminate harmful microorganisms and extend the shelf life of the juice. It involves heating the juice to a specific temperature for a designated period of time, followed by rapid cooling.

This process effectively destroys bacteria, viruses, and molds that may be present in the juice, reducing the risk of foodborne illnesses. By implementing pasteurization, we’re able to provide our customers with a safe and high-quality product that meets their expectations.

It’s our commitment to prioritize their well-being and satisfaction by ensuring that our juice products are free from any potential health hazards.

Blending Different Fruit Juices for Desired Flavors

In the process of industrial juice manufacturing, various fruit juices are combined to create the desired flavors. Blending different fruit juices allows us to create unique and delicious combinations that cater to the diverse tastes of consumers. To achieve the desired flavors, we follow a precise and methodical approach.

Here are the steps we take to blend different fruit juices for desired flavors:

- Selecting the fruits: We carefully choose fruits that complement each other and create a harmonious blend of flavors.

- Testing and adjusting: We conduct taste tests to ensure the right balance of sweetness, acidity, and other flavor characteristics. If necessary, we make adjustments to achieve the desired taste profile.

- Quality control: We perform rigorous quality checks to ensure that the blended fruit juices meet our high standards of taste, consistency, and freshness.

Adding Sweeteners or Natural Flavorings

One option for enhancing the flavors of blended fruit juices is to incorporate sweeteners or natural flavorings. Adding sweeteners can help balance the acidity of certain fruits and provide a more pleasant taste. Natural flavorings, on the other hand, can add depth and complexity to the juice.

When selecting sweeteners, it’s important to consider the desired level of sweetness and the target audience’s preferences. Common sweeteners used in industrial juice manufacturing include cane sugar, beet sugar, and high-fructose corn syrup.

Natural flavorings, such as extracts or concentrates derived from fruits, can be added to enhance the fruit flavors or create unique combinations. It’s crucial to carefully measure and mix the sweeteners or natural flavorings to ensure consistency and quality in the final product.

Adjusting the Acidity Level of the Juice

Now let’s discuss the points regarding adjusting the acidity level of the juice.

One important consideration is determining the optimal pH range for the desired juice product. We need to carefully assess whether the juice should be acidic or alkaline based on the desired flavor profile and consumer preferences.

This step plays a crucial role in achieving the desired taste and balance in the final product.

Optimal Ph Range

To achieve the optimal pH range and adjust the acidity level of the juice, we carefully measure and control the concentration of acid using precise techniques. Maintaining the right pH is crucial for ensuring the quality and stability of the juice.

Here are three key considerations in achieving the optimal pH range:

- Acid concentration: We determine the initial acidity level by measuring the concentration of acid present in the juice. This is done using titration methods, where we add a base solution to neutralize the acid and determine its concentration.

- pH adjustment: Based on the initial acidity level, we adjust the pH by adding acid or base solutions. This is done gradually, with regular pH measurements to ensure precise control and prevent overcorrection.

- Monitoring and testing: Throughout the process, we continuously monitor the pH level to ensure it remains within the desired range. We regularly test samples from different production batches to validate and adjust our methods if necessary.

Acidic or Alkaline?

After carefully measuring and adjusting the pH of the juice to achieve the optimal range, we now focus on determining whether it should be acidic or alkaline. This decision is crucial as it directly affects the flavor, shelf life, and overall quality of the juice.

To make this determination, we consider the type of fruit used and the desired taste profile. Citrus fruits, such as oranges and lemons, are naturally acidic and provide a refreshing tang. On the other hand, some fruits, like apples and pears, are naturally sweeter and less acidic.

Packaging the Juice Into Containers

We package the juice into containers using an automated process. This ensures efficiency and consistency in our production line. Here is a step-by-step guide on how we package our juice:

- First, the juice is carefully transferred from the holding tanks to the filling machines.

- The containers, whether they’re bottles or cartons, are sterilized to maintain the highest level of hygiene.

- The automated filling machines accurately measure and fill the juice into the containers, ensuring precise quantities are maintained.

Labeling and Coding the Juice Bottles

One important step in our industrial juice manufacturing process is labeling and coding the juice bottles using a reliable and efficient system. This ensures that our products are properly identified and traceable throughout the supply chain. We implement a three-column, four-row table to illustrate the details of our labeling and coding process:

| Column 1 | Column 2 | Column 3 |

|---|---|---|

| Bottle Type | Production Date | Expiry Date |

| 250ml | 28/02/2022 | 27/04/2022 |

| 500ml | 15/03/2022 | 14/06/2022 |

| 1L | 07/03/2022 | 06/09/2022 |

For each bottle type, we print the production date and expiry date on the label. This allows consumers and retailers to easily identify the freshness and shelf life of our juice products. The labeling and coding process is performed with precision and accuracy to ensure compliance with industry standards. By implementing this systematic approach, we prioritize the quality and safety of our juice bottles, serving our customers with confidence and reliability.

Conducting Quality Control Tests

Moving forward in our juice manufacturing process, we conduct quality control tests to ensure that our products meet the highest standards of freshness and safety. These tests are essential in guaranteeing the quality and consistency of our juices.

Here are the key steps we follow in conducting our quality control tests:

- Sampling: We take representative samples from each batch of juice for analysis.

- Microbiological Testing: We test the samples for the presence of harmful bacteria or pathogens.

- Chemical Analysis: Our experts perform tests to assess the sugar content, acidity levels, and other key parameters.

By meticulously conducting these tests, we can identify any potential issues or deviations from our quality standards. This allows us to make necessary adjustments and ensure that our customers receive the best possible product.

Our commitment to quality control is a testament to our dedication to serving our customers with the highest level of satisfaction.

Storing the Packaged Juice in Proper Conditions

After conducting quality control tests, we ensure that the packaged juice is stored in proper conditions to maintain its freshness and safety. Our facility is equipped with state-of-the-art storage units designed specifically for juice products. These units are temperature-controlled to maintain a constant temperature range between 34°F to 40°F (1°C to 4°C), which is ideal for preserving the quality and taste of the juice. In addition, the storage units are equipped with proper ventilation systems to prevent the buildup of moisture and odors.

We also implement a first-in, first-out (FIFO) system to ensure that the oldest stock is used first, minimizing the risk of spoilage. By storing the packaged juice in these optimal conditions, we can guarantee that our customers receive a product that’s fresh and of the highest quality.

This brings us to the next step in the process, which is distributing the juice to retailers or wholesalers.

Distributing the Juice to Retailers or Wholesalers

So, how do we distribute the juice to retailers or wholesalers?

The process of distributing industrial juice requires careful planning and coordination to ensure that the product reaches its intended destinations efficiently and in pristine condition. Here are the steps involved:

- Logistics: We collaborate with logistics partners to devise an optimal distribution plan, taking into account factors such as transportation modes, routes, and delivery schedules.

- Packaging and labeling: The juice is packaged in sturdy containers that protect it from external factors during transit. Each package is labeled with essential information, including product details, expiry dates, and batch numbers.

- Quality control: Regular quality checks are conducted to ensure that the juice meets the desired standards before it’s shipped out. This involves inspecting the packaging integrity, taste, color, and overall product quality.

Monitoring and Improving the Manufacturing Process

To begin monitoring and improving the manufacturing process, we conduct regular evaluations of our production methods and implement necessary adjustments. We analyze each step of the manufacturing process, from sourcing the raw materials to packaging the final product. This allows us to identify any inefficiencies, bottlenecks, or quality issues that may arise.

We use various tools and techniques, such as statistical process control and root cause analysis, to gather data and pinpoint areas for improvement. By closely monitoring key performance indicators, such as production yield, cycle time, and defect rate, we can identify trends and patterns that indicate potential issues.

We also actively seek feedback from our employees and customers to gather insights and suggestions for improvement.

Through this continuous evaluation and improvement process, we strive to optimize our manufacturing process and deliver the highest quality juice to our customers.

Frequently Asked Questions

How Are the Raw Fruits Harvested and Sourced for Industrial Juice Manufacturing?

We source and harvest raw fruits for industrial juice manufacturing by carefully selecting farms and suppliers that meet our quality standards. Our team ensures that the fruits are picked at peak ripeness to maximize flavor and nutritional value.

What Methods Are Used to Sort and Clean the Fruits Before Juice Extraction?

We use various methods to sort and clean the fruits before juice extraction. These methods ensure that only high-quality fruits are used, reducing the risk of contamination and ensuring a safe and nutritious product for our customers.

How Is the Juice Extracted From the Fruits?

We extract the juice from fruits using a mechanical process called juice extraction. It involves crushing or pressing the fruits to release the liquid. This method ensures maximum yield and efficiency in our industrial juice manufacturing.

What Techniques Are Employed to Filter the Juice and Remove Impurities?

To filter and remove impurities from juice in industrial manufacturing, we employ various techniques, such as sedimentation, centrifugation, and filtration. These processes ensure that the final product is pure and free from any unwanted substances.

How Is the Juice Pasteurized to Ensure Consumer Safety?

To ensure consumer safety, we pasteurize the juice through a meticulous process. The juice is heated to high temperatures, eliminating any harmful bacteria. This step protects the health of our valued customers.

Conclusion

In conclusion, the process of industrial juice manufacturing involves several precise and methodical steps. From the selection and washing of fruits to extraction, pasteurization, and packaging, every stage is carefully monitored to ensure quality and safety. The industrial juice manufacturing process also incorporates advanced machinery and automation to optimize efficiency and maintain consistency in flavor and texture. These steps ensure that the final product meets both consumer expectations and regulatory standards.

While some may argue that this process is too complex and time-consuming, the visual representation of these steps clearly demonstrates the importance of each stage in ensuring the quality and safety of the final product.

By following these detailed procedures, manufacturers can produce delicious and nutritious juices that meet the highest standards in the industry.

Susannah expertise lies in researching and compiling evidence-based content on juicing, nutrition, and overall health. She is committed to ensuring that The Juicery World offers accurate, up-to-date, and trustworthy information to empower readers to take control of their health. Susannah’s goal is to inspire individuals to embrace juicing as a way to nourish their bodies and live their best lives.

-

Popular Juice Brands5 hours ago

Popular Juice Brands5 hours ago9 Best No-Sugar-Added Popular Juice Brands

-

Juice Manufacturing Process6 hours ago

Juice Manufacturing Process6 hours ago14 Detailed Steps in Industrial Juice Manufacturing

-

Vetted2 months ago

Vetted2 months ago15 Best Juices for Diabetics: Refreshing Options That Won’t Spike Your Blood Sugar

-

Juice Tips and Tricks22 hours ago

Juice Tips and Tricks22 hours agoHow To Get Juice Wrld Skin Fortnite

-

Vetted2 months ago

Vetted2 months ago15 Best Decaf Coffee Options for Flavor Lovers Who Need a Caffeine Break

-

Vetted2 months ago

Vetted2 months ago15 Best Espresso Ground Coffees to Elevate Your Morning Brew

-

Vetted2 months ago

Vetted2 months ago15 Best K-Cup Coffee Pods for a Perfect Brew Every Time

-

Juice Tips and Tricks19 hours ago

Juice Tips and Tricks19 hours agoUnlocking Health Benefits with Onion Juice – A Guide